Oops! I knew I’d get into troubles posting pricing. There are a lot of different processes available through which you can get a 3D model made and it’s important that you compare apples to apples. To name just a few: Polyjet (which is what Objet & the Dimension Printer Hiroshi used are), Sterolithography/SLA (which is what dread_companion had made), Fused Deposition Modeling/FDM, Laminated Object Manufacturing/LOM, starch/paper pulp based & wax jetting printers (ZCorp), and so on & so on. Each process has it’s own unique characteristics and some are better suited for sculptural development than others.

The SLA process claims a Z axis resolution of .001"-.002" but I do not know of any place that actually runs their machines within that calibration (typical SLA resolution is around .004"-.008"). The laser which polymerizes the SLA resin also degrades over time which can effect build quality and resolution immensely depending on it’s age.

Also there are rigid support posts that need to broken from the model after building which requires post finishing to remove both the build lines or grain from the poor resolution and the stubs from the support posts. While the figure dread_companion had made may be longer in one axis than the T-Rex, material consumption is based on volume which I would think the T-Rex head may be slightly larger. I would be happy to post a quote for dread_companion’s piece using our process for comparison.

Regardless, for models that accuracy is not an issue, do not have much detail, or you do not mind doing (or paying for) post finishing, SLA is certainly an option. I don’t want to come off like I’m saying Objet is the only way to go but it absolutely has the finest resolution and highest accuracy of any of the processes currently available and the support material is more like a nest for the model and is not geometrically attached in any way so there is no sacrifice of surface quality from support post removal. In my honest opinion, there really is no match to Objet for reproducing top notch quality & highly detailed pieces.

Our newest Objet machine offers a high quality (standard) & a high speed setting. The high speed setting cuts the resolution from .0006" down to .0012" which is still finer than any other process. For models that do not require the high resolution detail of the standard setting, this setting can offer big cost savings. A single T-Rex head would be around $170 and 5 would be around $125 each. So if economy is your driving factor I still think Objet is the way to go.

And yes, you can prime, paint, and stain both the standard Objet & SLA materials perfectly (the Dimension printer has a wax ingredient which can make painting difficult). On models where you want fine details preserved, priming & painting tends to fill those in. This is another reason I like the Objet material selection better because you have options of material base color and it readily accepts paint without priming first.

Anyone who is in (or visiting) the Chicago area is welcome to come by to view our facility, the process, and our Objet machines. I’m also available to talk in detail about any questions regarding rapid prototyping, the technology, manufacturing, or development in general. Just ask for Josh Harker. I’ve been in the business going on 20 years. You can find all our contact info here-http://www.pardev.com/contact.html.

I hope my long winded posts have been helpful in explaining the process.

Cheers!

Shhark

*Shipping overseas is not a problem.

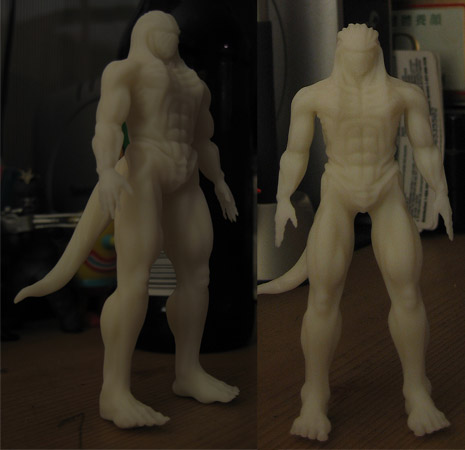

What I want to do with my master, is to make a mold off it, and make ‘copies’ that I won’t feel bad if I mess them up. Since I’m a klutz with anything manual (thank the cosmos for digital!), I’m also afraid of doing those molds myself. But I guess at some point I will have to get my hands dirty

What I want to do with my master, is to make a mold off it, and make ‘copies’ that I won’t feel bad if I mess them up. Since I’m a klutz with anything manual (thank the cosmos for digital!), I’m also afraid of doing those molds myself. But I guess at some point I will have to get my hands dirty