Mike PCI

AMAZING!!

That’s very small and delicate.

These guys will be printed out, then spincast in pewter. They’ll be 37mm tall

http://www.3d-miniatures.com/tiki-browse_gallery.php?galleryId=3

Mostly done in Zbrush, the gun, grenade and knives done in MOI.

[ ]

]

Crusoe the Painter

In pewter! I want to see it!

[ ]

]

Attachments

How are they? I would like one.

I like the picture of them in the little Box with all there fingers up.

When I was 13 I worked for a guy that made lawn ornaments out of cement.

I learned alot about molds and forms. Pretty Funny that at 13 I was Painting Concrete geese and deer now I cringe every time I see one on a porch

Very cool toys ya got there. We have that machine at work in our CAD room.

I’m defiently going to try to print something when I go back to work. Never tried it. I seen a few things printed off but nothing like that.

looks like alot of work, but very rewarding… cool stuff… it’s interesting to see zbrushing crossing over into physical craft

it might be that i love everything made by japanese people, but this stuff is pure gold

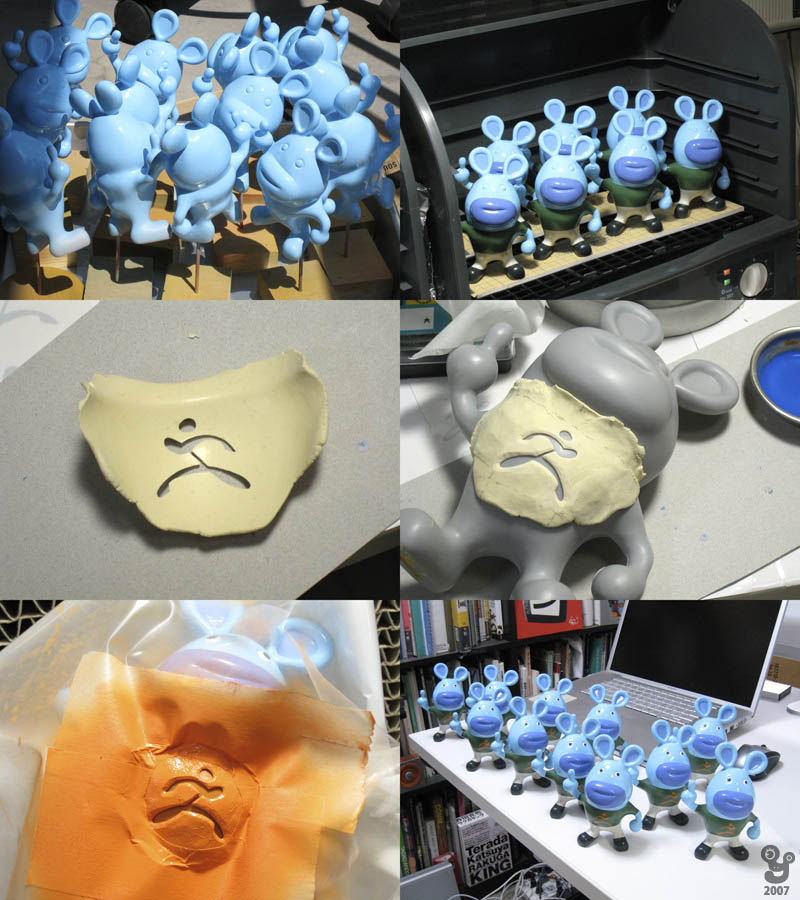

About these 2 toys, I used ZBrush for original design. But I used other 3D program mainly for 3D print.

Attachments

That’s all. THANKS.

Attachments

This should definitely be a top row thread. There aren’t a lot of people showing off this side of Zbrush. Great work, I hope you sell a lot of them.

of techniques. Very interesting process. I love it!

Hi All-

We do 3D printing! My company is Paradigm Development Group, www.pardev.com. We also do CAD development, CNC machining, finishing, molding, casting, painting, etc, etc… We are located just outside Chicago. We have 2 “Objet” 3D printers and currently offer 8 materials to choose from (translucent amber, white, black, blue, 3 rubber elastomers & a polypropylene-like material). In my honest opinion (not just because it’s my company) the Objet is the best technology available based on material choices, accuracy & it’s incredible resolution (.0006" Z axis layer thickness!). The next closest process (SLA) only offers .002"-.006" layer thickness. Ultimately we need an .STL file to build from but if you don’t have the software to convert we can do it here from the native .ZTL file (it would be awesome if Zbrush had an .STL export module!). I have printed a few ZB models in the past and have posted on them. I haven’t had a chance to do much with ZB3 recrently but have a couple of projects that I plan to print soon and will post when they’re done. The attached images (sorry for the crappy quality) of the t-rex & tangle were ZB models while the other 2 were built in Solidworks, all were printed on our Objet machines and have had no post finishing. They are right off the machine with only support material removed. I am happy to go into detail about the process with anyone interested. By the way, great work and awesome thread Hiroshi!

Viva la Zbrush-

Shhark

Attachments

That’s cool. So what do you do, export OBJ from ZBrush, import it into Solid Works and print from there or do you export as an STL and print in another app? I have Rhino 2 and I could probably get a few files from ZB3 into it. It’d be neat to have an alternative printer a bit closer to home (3d art to part is in Cali…too far from NYC).

I plan on getting some stuff done with your company shhark, I figure this is the place to ask questions so everyone gets the anwsers so…

-can you give a rough cost, say for that t rex?

-what are the advantages and diadvantages of the different materials?

-oh and I live in Canada is that ok for shipping?

those materials look awesome! resolution too! any info on pricing? it probably has to be quoted different for every piece but any guidelines?

edit

mphilip beat me to it

I’m really intersested too, but:

- I’m from Europe… so is there a way to access your services.

- Your website doesn’t give any idea of price.

3D print is the next step… I really hope to touch something ‘made in mybrain’ a day…

Exporting to OBJ from ZB then into Solidworks through an OBJ import plugin module, then export .STL from there. If original Zbrush model is poorly built (overlapping meshes, holes, etc) we do repairs in Magics by Materialise. It can get to be a pain but it’s proven to be a reliable pipeline. Generally, if you know you’re going to go 3D with your model and construct your model accordingly, the better luck we have when exporting to .STL. It would be great if there was a plugin for Zbrush for .STL exports (anybody talented or motivated enough in this area to pull it off?!) I know Zbrush wasn’t originally developed for this application but why not push the envelope?

Costs for printing vary wildly from as little as $50 to well over $5000. Size, geometry, material choice, and quantity drive costs directly. I hesitate to post pricing just because this will be up for all eternity while our prices may change in the future as material prices go up & down. Best case is to send me a file and I can quote you directly for the model you like to have done. For reference though, a single Trex head (3.33" x 2.32" x 1.33") would cost around $250 in a standard rigid material, but 5 of them would cost approx. $700 or about $140 each. Again, material prices tend to fluctuate year to year and every model tends to have it’s own circumstances that dictate pricing.

Parts are generally printed & shipped within about 1-3 days depending on our backlog. We offer free quotes, accept credit cards & can ship internationally. We require pre-payment for new customers.

Material advatages vs. disadvantages really comes down to which material works best for your application. The standard rigid materials are all basically the same except for color, while the polyproplylene-like material offers better flex properties usually associated with snap fits and living hinges. The elastomers are good for simulating rubber parts like keypads & gaskets but can be fun for vinyl like prototypes but cannot be painted effectively. We have the material properties of most of the materials available on our website if you need more info @ http://www.pardev.com/datasheet.html.

If you’ve got something you would like to have quoted please contact us through our website @ www.pardev.com for more info (ask for Josh Harker). It would be really cool to see all this amazing work everyone has been doing with Zbrush in full 3D form (getting goosebumps)!

Shhark

Thanks for the info! I’ll be sure to call on you guys when I have something to print.