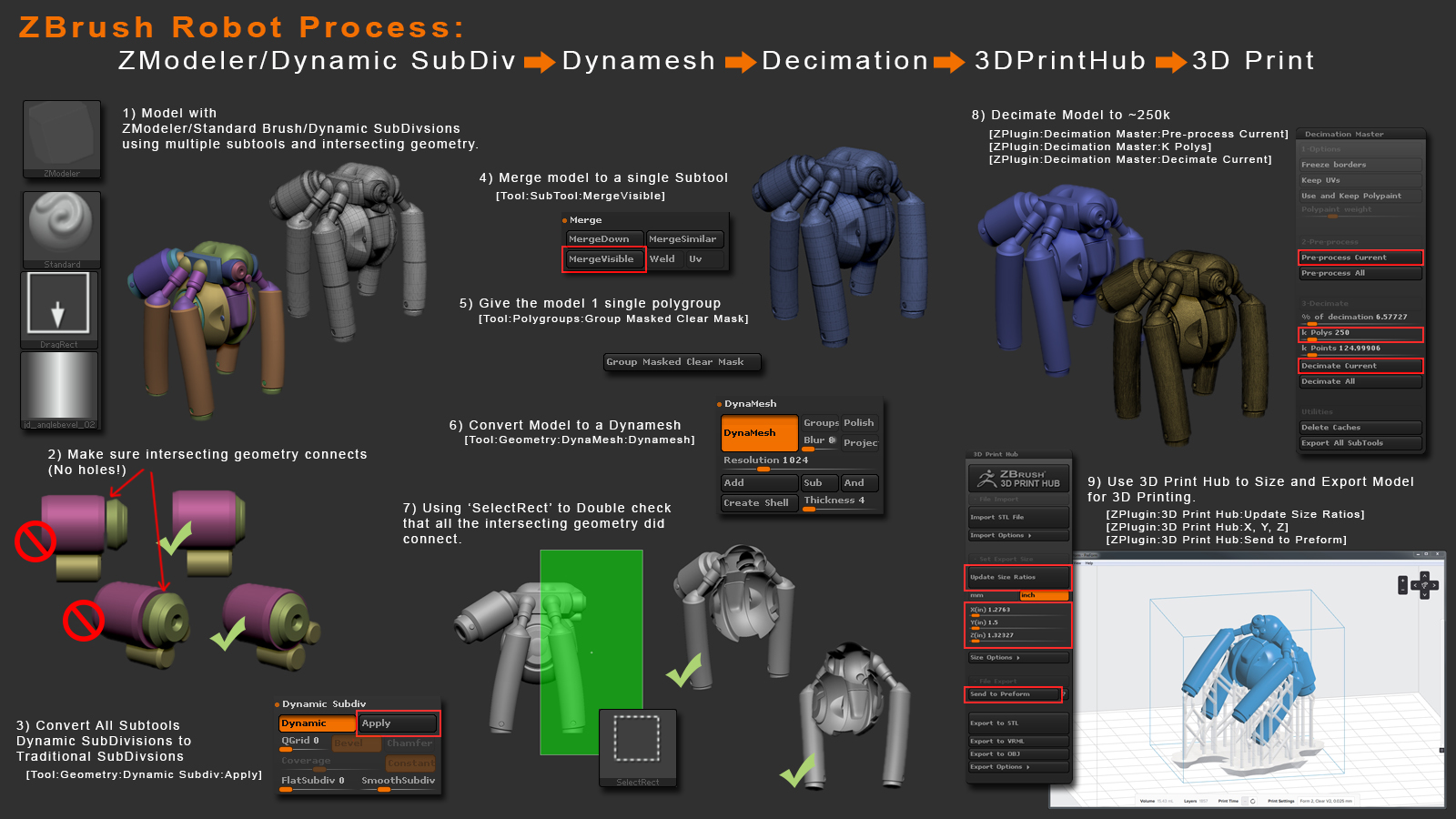

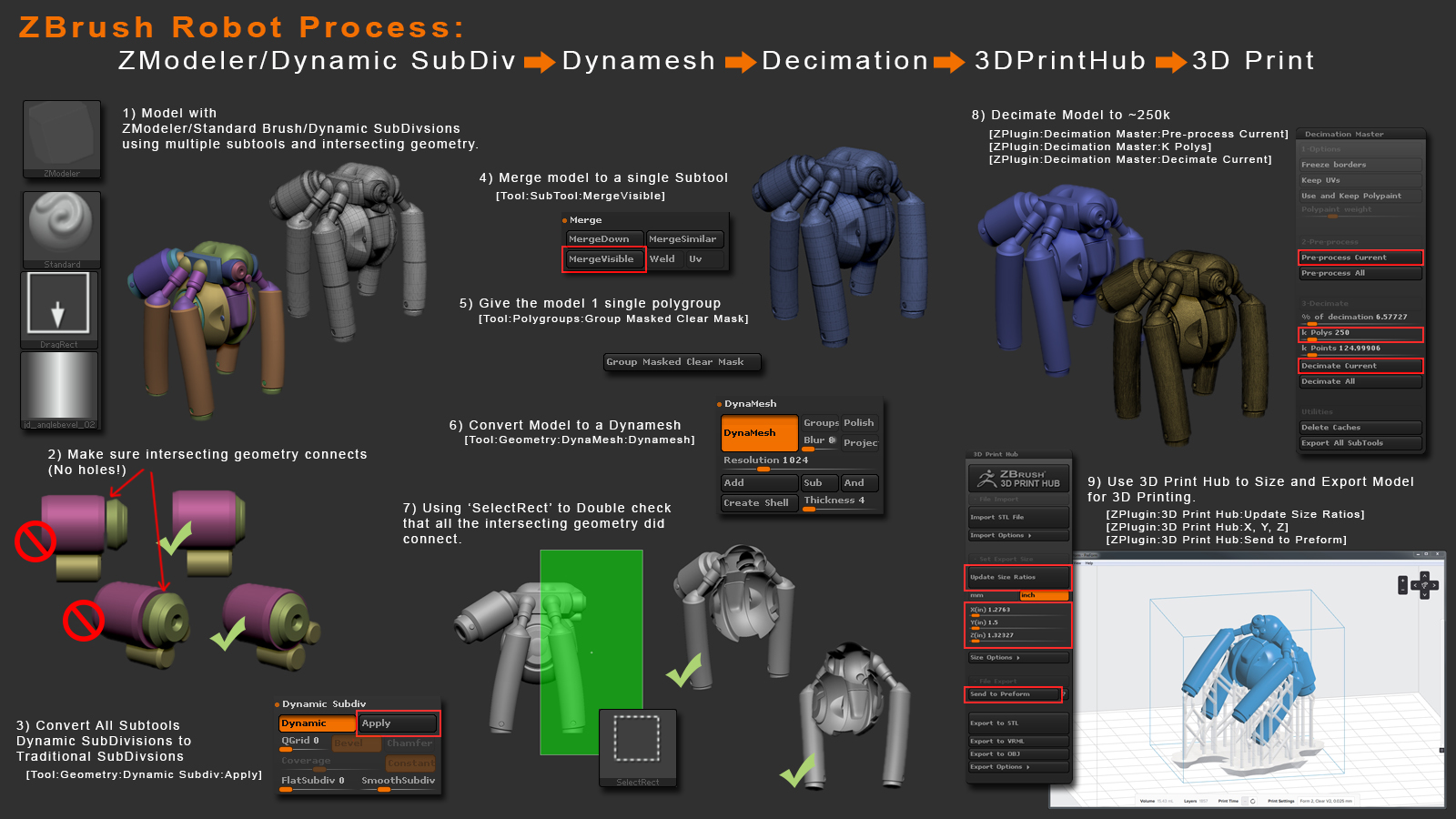

@slothkins, @MealeaYing: Here is a quick image breakdown of the process

The main thing for 3D Printing is to make sure any intersecting geometry is solid and intersecting correctly. Then after the modeling is completed I merge all the subtools together then convert them to a Dynamesh. Dynamesh will weld everything together, get rid of the internal geometry, and generate a watertight mesh. After the Dynameshing is done I just check to make sure that it is indeed solid then I decimate it down to around 250k. After that I just export and print.

Shapeways/Sculpteo both check with a lot of scrutiny to make sure that the print doesn’t fail (since failure is money and time lost for them.) I find that some of the restrictions often times will print fine on a consumer level printer.

-Joseph

Attachments