Hi Tomas, sorry I didn’t get back to you. A lot of interesting info here, thank you. I appreciate it. I’m probably asking too many questions because you didn’t see this first one…I’ll rephrase…

- Can the material that 3d printers use work for the casting house to make the proper mold? Is Dimension the only 3D printer you’ve tried? How about Polyjet which is a different material I believe?

I ask all these questions because if I want to try something similar, the 29K 4 axis thing isn’t in my reach. But knowing people locally who have a polyjet is possible for me.

-

Oh you pay a monthly bill to casting house? Is that for storage of your existing molds they made for you in the past? Is it so they can consistently keep pouring new silver rings for you? Expensive? Sorry about prying…I’m a whore for gathering details…lol

-

How many pieces of jewelry are you selling every month?

-

I think to prevent polygon cruncher from choking out, you need to batch import & be using the x64 version. I use this version with 8GB of ram and it hasn’t been a problem for me.

-

Cool what did you do in Hollywood? Work for a special effects house?

-

I apologize. I guess I should’ve known better when you said you couldn’t show examples of the work you helped to “shadow design”. I didn’t think of it like that. Even showing who you worked for could get you in trouble. That’s a shame. Even work you might be proud of can never be known that you did it. But it did pay a lot so that’s cool.

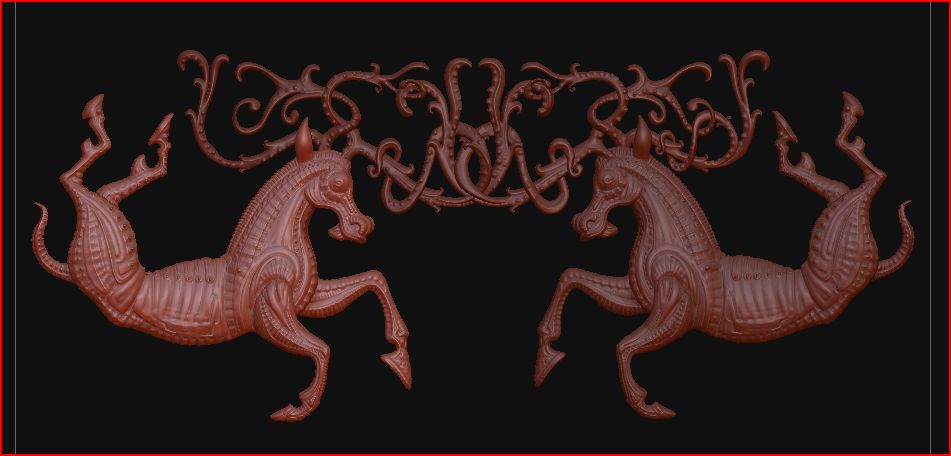

Thanks again for all the info you share. Can’t wait to see those build-up pics or whatever you call them.