Hello fellow Zbrushers, while trying out the MMs the community provides, i encountered a Problem containing the Rotation i get when inserting sertain Multi meshs: Is there an Option to Change the Rotation of imms?

Is there an Option to Change the Rotation of imms?

Hi everybody. I’m having some issues with the workflow.

EDIT: Not having any issues anymore. I finally learned by clicking in the subtool once to finalize it and the stroke disappears!

However, can you go back and modify the mesh once it is “finalized” so to say? Go back and modify the stroke, replacing, scaling etc? or once you’ve clicked it, there’s no going back?

I assume not cause you’ve created new meshes inside the subtool itself and thereäs no history to the stroke anymore?

Is there a short and easy way to separate the newly created meshes into own subtool?

Having to duplicate and deleting is pretty annoying =/

Thanks!

Yep!

Go into the SubTool Pallet and look under Split, Use Split To Parts (this might be a bit much if you have lots and lots of “parts”). Each polygroup will be split into a separate subtool.

Each time you use a insert brush it adds a new polygroup for that stroke which you can then do all sorts of cool things with.

Thanks alot!

If your using a tri-part insert, you might not want to split that up as it has 3 polygroups, so another alternative might be to ‘Ctrl+Shift+click’ to hide the part you want to split then in ‘Tool > Subtool >Split’ click ‘Split Hidden’.

ps: Hya Mealea!

|Sooo…

|

I have a couple of questions that are partially on topic and partly off topic but sort of related sort of…

The first part is what to do with Micromesh things, in my case I made a bit of cloth that can be used as micromesh to make some fairly good cloth, its not an insert however but its sort of the same idea, should I put it in the Insert brush repository or not? Oh, and if not where would be better? Making another thread seems a bit much but its obviously not a mesh insert (and actually screws up as one, too many poly groups I think)

The other part of the question is more complicated and sort of a request, you know how with an open ended mesh insert you can weld the open bits together? Is that possible with Micromesh and if not could it be made to be?

What I am seeing is gaps between each bit of mesh and it interrupts an otherwise potentially perfect flow.

In this example Im dealing with I made that segment of cloth but there are gaps between the segments that cause problems later like after doing BPR to Geo in the Geometry pallet.

Does this even make sense?

I can post pictures if needed.

[Aurick, if this belongs in the Troubleshooting section let me know and I will move it ok?]

Cheers!

Mealea

PS: Hya ZBER!!!

|

Hi Mealea

Something you might want to look into is ZWelder by Piggyson (Joseph Drust). I’m not a 100% sure about this, but I think he uses it in his Micromesh Hood tutorials.

OK, I just watched the tutorials again and he starts getting into using ZWelder at minute 6:55 in the Micromesh Hood Part 2 video.

|ZBer that is SO CLOSE!!!

|

I watched the whole thing, its great!

But its not quite doing it, he is using a one sided object and Im not and I think that is where I am running into problems…

Im trying to make a connecting weave that results in continuous geometry (like his does after exporting and importing) but mine has depth and the edges are not welding, also I have more than one polygroup because each thread or strand needs to be able to be edited later, what I am ending up with is each instance of the mesh I am using for the micromesh is coming out as a separate meshes (thousands of them) and that kills it.

They don’t weld, they don’t dynamesh and they don’t ZRemesh… so far.

The other thing I am wondering is whether I need total precision on the ends of the strands, this is something I have no clue how to accomplish in ZBrush, and I don’t want to make micromesh things in something else for a number of reasons, mainly I hate leaving ZBrush.

This is the file, once you see it on an object as micromesh you will see how its failing, the best way to see it is to use the smooth brush, but you can see it in other ways too such as by subdividing it.

MicroMeshCloth.zip (14.3 KB)

[ EDIT: I may be seeing some welding, but not to and from the correct points and suddenly I think I know why, that whole thing about Spin Edges, I bet that the little welding I am seeing is not happening correctly because my objects are not lined up in the same directions! If that is the case Im screwed because while in his tutorial he does this with a small grid of polygons for making an Alpha I am using full objects that have a million or so polygons. I bet that is what it happening!

Oh crap! ]|

MicroMeshCloth.zip (14.3 KB)

I confirmed that last bit about needing to use Spin Edges.

It looks like I might be screwed.

I think where you are having the problem is that you have closed geo where it should be open. If you are going to use it for ‘micromesh converted to geo’ then everything around the outside will have to be open or it might not weld properly. This is true for most 3D apps. Also, you have slightly overlapping geo and I think it is confusing ZBrush as what to weld and what not to weld.

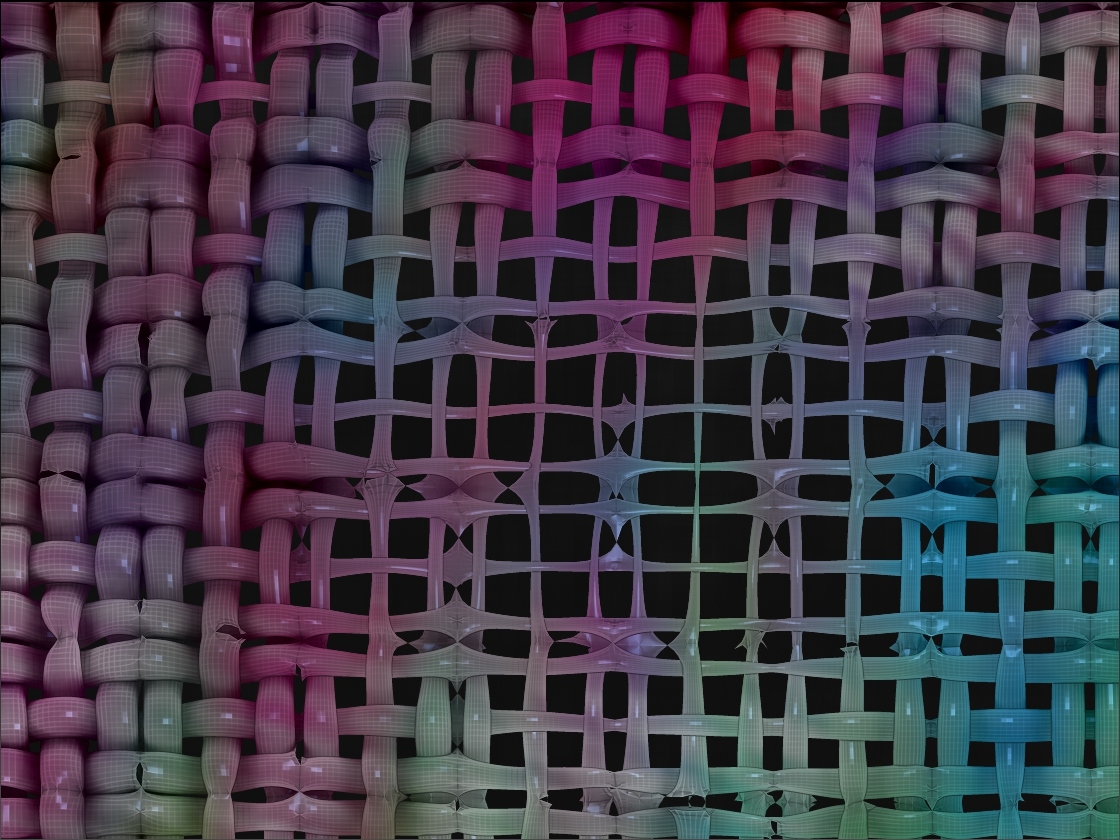

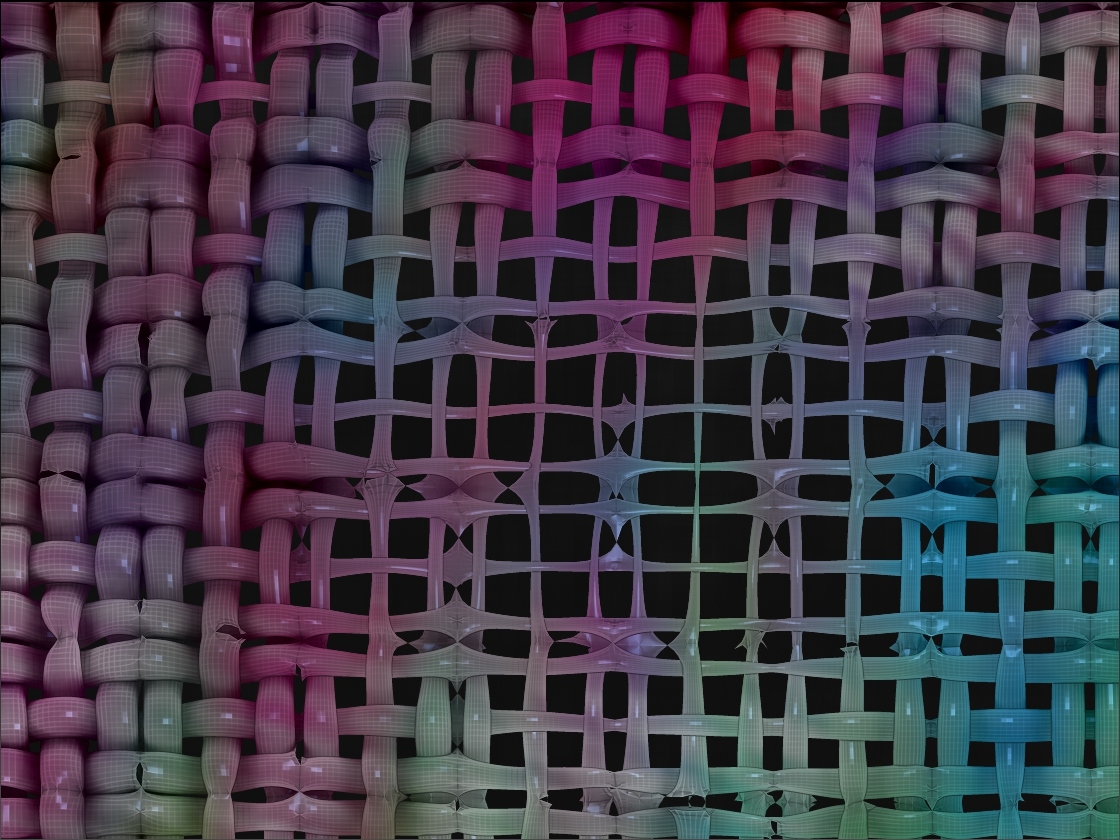

edit: add image

This is what I get, using your ztool, when I use ‘micromesh converted to geo’ then welded using ZWelder and then subdivided twice. Is this the same as what you get?

|EDIT:

|

I tried ZWelder again and this time it worked mostly!

I think the difference was that I had not opened anything from a folder different then where ever ZWelder stores things… or something… honestly I have no clue…

I did do some welding and seems to have worked FAIRLY well, but with some exceptions where some points seem to be welded to the wrong place, this happened before but more so, I think what I need is that bloody Spin Edge thing automated somehow, I don’t quite see spinning the edges of many millions of polygons by hand… if that is even the problem!

PROGRESS!!! YAY!!!

Half of this post was deleted for no evident reason.

ZBC is a weird bit of html…

So here’s the other blasted part:

Do you mean the ends of the strands need to be open? or all of the stuff on the edges including the sides of the strands?

Your result looks great but I would love to see it after you use the smooth brush on it, using the smooth brush makes it look “threadbare” but it also shows where points weld funny…

If you have opened the sides of the strands they will merge into one wide one which is somewhat undesirable, I think that could be fixable by moving them in from the edge however. The problem there is that this is designed to be sort of dense cloth that can be thinned out later.

Hmmmmm…|

This is what I get when I smooth the hell out of it using the Smooth brush.

What I did…

-

Load your ztool.

-

Select a Plane3D and make it a PM3D.

-

Reconstruct Subdiv twice but only for demonstartion purposes to keep it light.

-

Went to ‘Tool > Geometry > Modify Topology’, clicked ‘MicroMesh’ and selected your ztool.

-

Turned on ‘Draw MicroMesh’ in ‘Render > Render Properties’.

-

Did a BPR render.

-

Clicked ‘Convert BPR To Geo’ in ‘Tool > Geometry’.

-

Used Zwelder to weld geo (no errors).

but, as you see where I used the Smoothe brush, it didn’t get welded everywhere. I don’t think that is ZWelders fault though.

Something else you might try is, making the ztool 2D, as Joseph Drust does. Weld that with Zwelder then Extract for thickness for 3D.

|You got the same problem I did, you see where it breaks right?

|

That happened to me too, but Im getting closer, I now have points from one strand jumping to another strand, but so few its like Im ALMOST there, but not quite, its weird…

The 2D thing is sort of out unless you mean making the same sort of object with a bunch of one sided objects, this IS possible I think, and while it would be I think harder to grab the ends of the strands to make the weave I think you might have the only answer.

This has subdivisions and smoothing but is the best example of using weld that I have managed so far:

|

Attachments

Im going to try to make a one sided one using a Plane3D reduced down using the initialize pallet, this should be interesting!

As it turned out that came out worse!

I tried your ztool again with all the same steps I had in post #93, but this time I lowered the Threshold slider in ZWelder to .002 before clicking ‘Weld Current Object’ and it looks like it did a decent job of welding. Same as before, I subdivided twice then used the Smooth brush.

ZBer, I have one that works, if you turn Weld up all the way in the import panel, but it comes out dented and strangely uneven.

The most interesting thing is what you get for polygroups in the end!

Give this one a try, I got it to work nearly flawlessly, but with some slight denting.

LastDitch.zip (11.2 KB)LastDitch.zip (11.2 KB)

I didn’t have much luck with your second one. No matter what I did, I kept getting the same thing.