i have an email out so hopefully I’ll be able to answer that soon

Any info yet?

not blowing you off … trying to find out, they seem to be busy

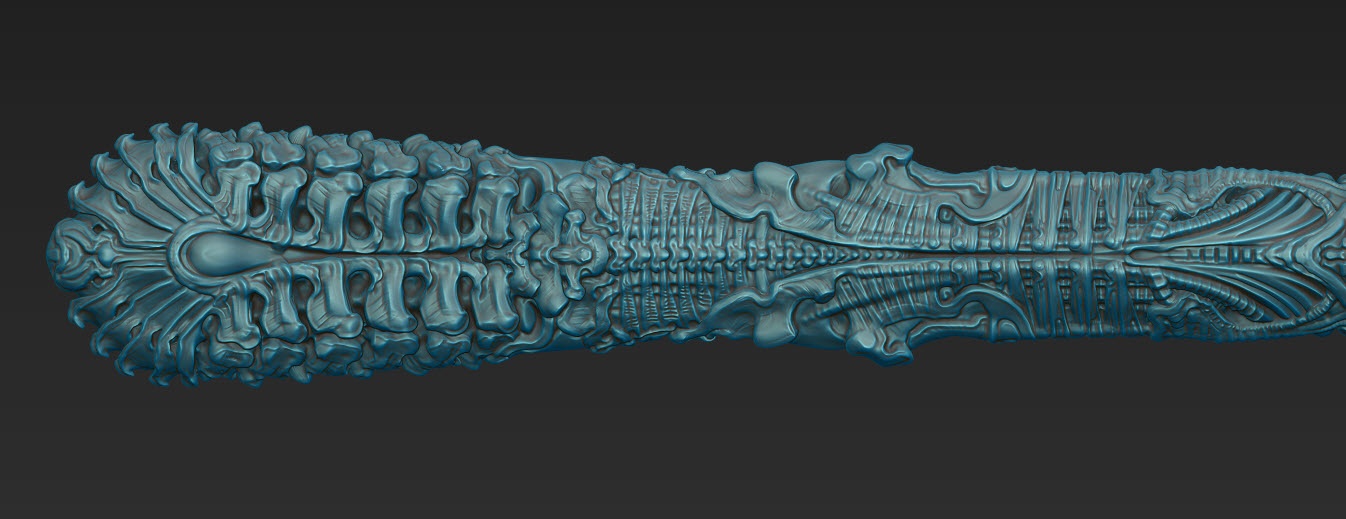

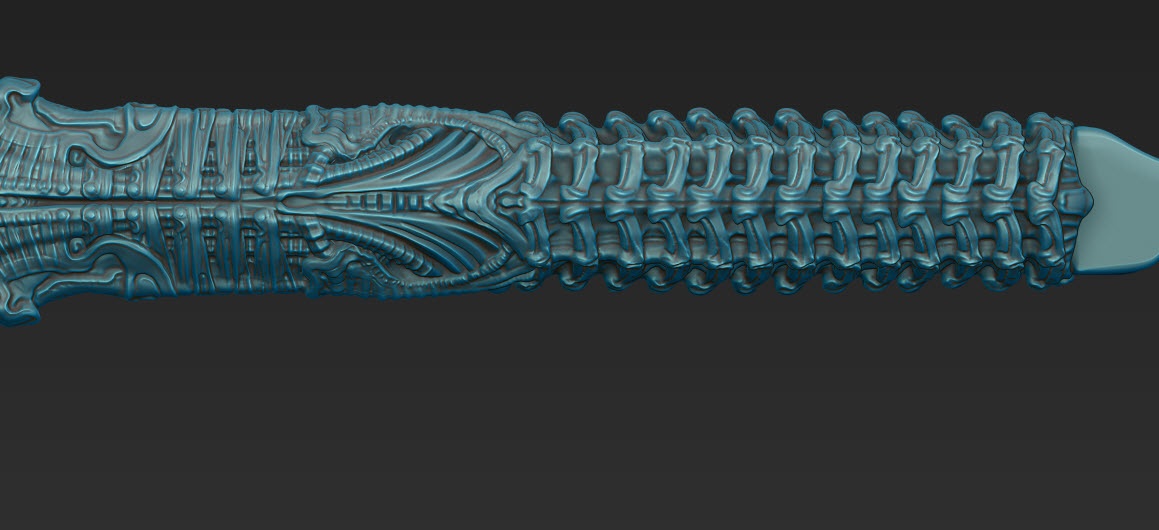

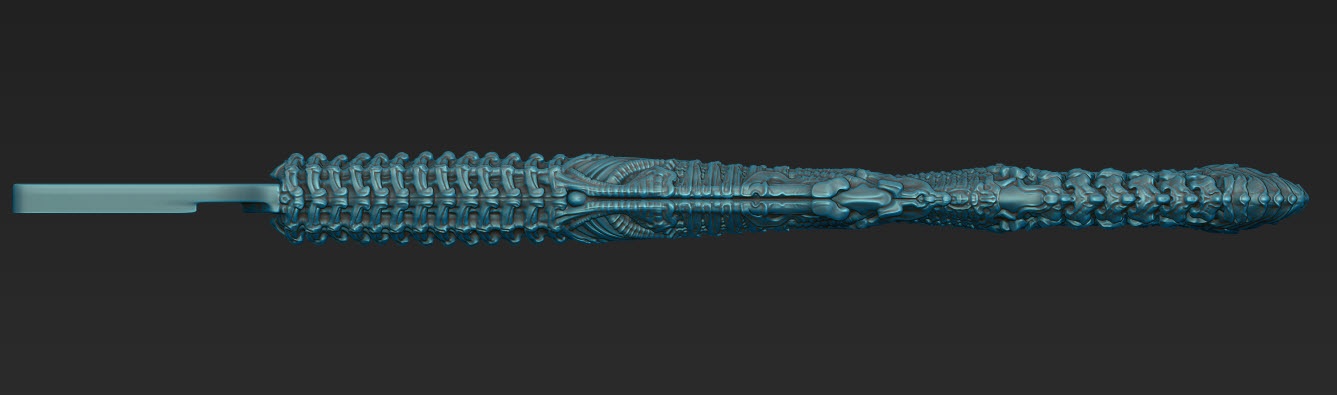

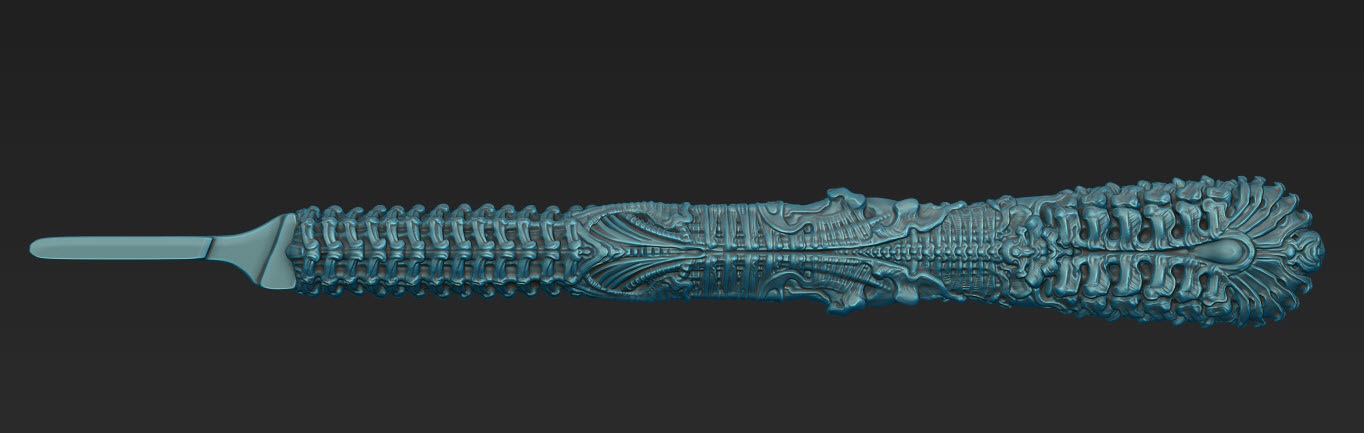

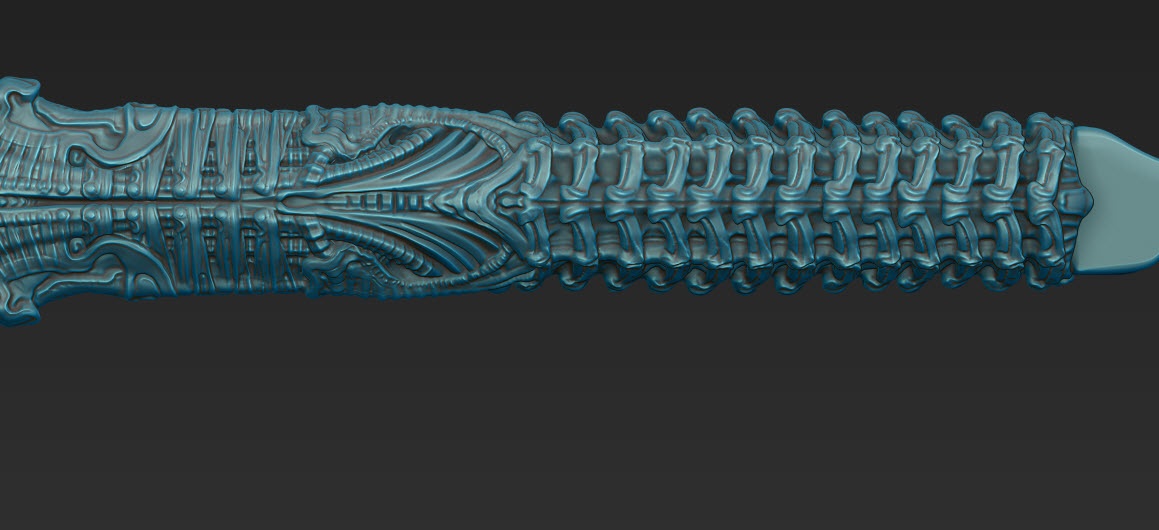

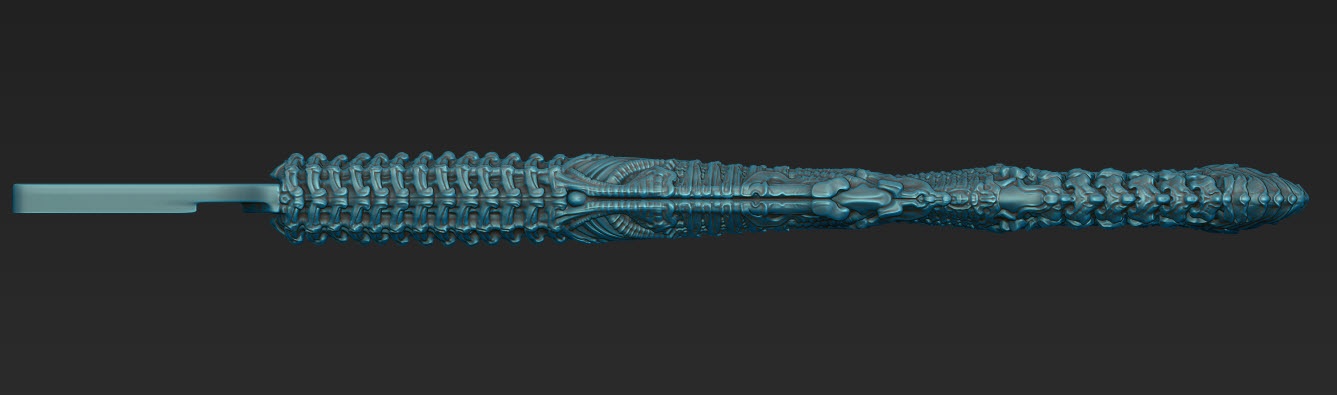

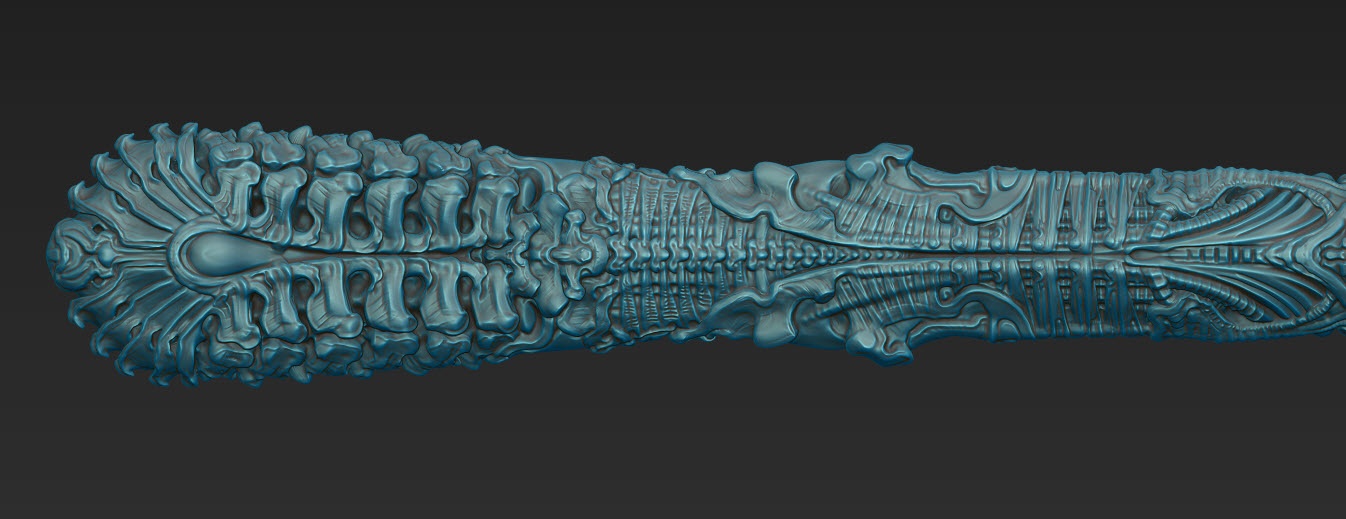

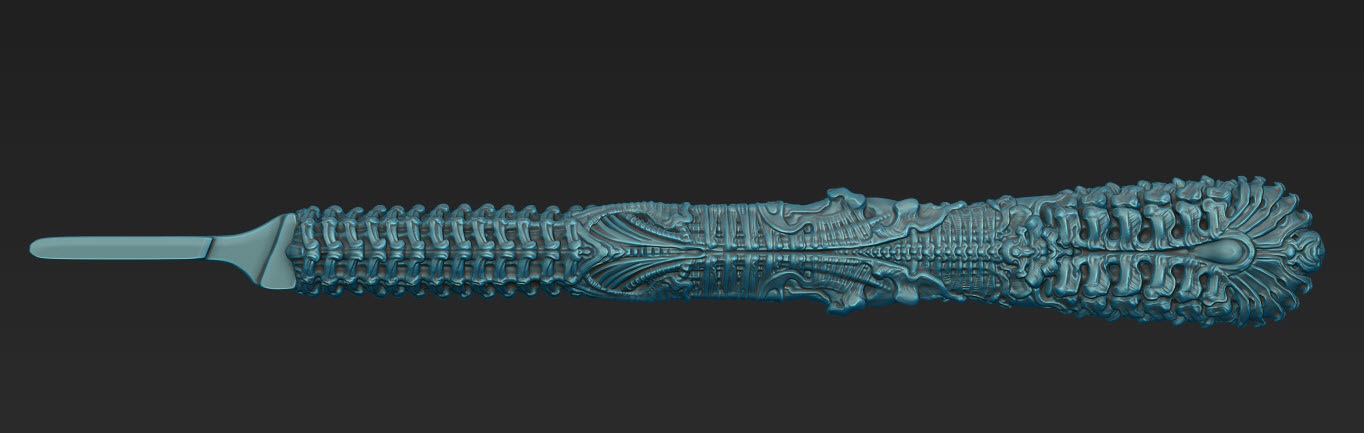

ok, on the big 3d systyems in two parts. laser centered nylon at 35um

here is the link to my new zbrush workshops / uartsy class

http://tomas-wittelsbach.zbrushworkshops.com/

It looks a bit rough for 35um, but looks awesome!

When does your class starts?

lmao… good eye

the preview is the 28th

the class the 13th

Did you ever make any of the Scalpel Blade Holders ?

Your Artwork is AMAZING

Newton

Cool Thread, Do you have any experience with the Form 2, 3D printer? Would the form 2 be a good investment for jewellery prints?

Newton - here is one a did for samppa, and thank you…

montana2008- i just got a test grow from form 2 and i am impressed enough to say it is the desktop printer i want. i haven’t held the castable resin but the detail in the plastic is lovely for a 3500 machine

Attachments

from Ryan

Hello! Not sure if I’ve told you about this. Last week was a bit busy setting up for Tomas Wittelsbach’s webinar.

But, My ZBrush Certification Hosted! course is now bundled with Tomas’ Live Jewelry course.

Go here to learn more.

The ZBrush Certificate Hosted! course is a new way to access the Certificate class. Basically, you get everything the Live version has minus participation in the LIVE session.

Tomas’ class is Live when you get the cert you get me training you on the basics of ZBrush so that you can rock it in Tomas class.

Have a great week,

Ryan

P.S. If you missed my webinar on the Certification program you can see it here:

https://www.zbrushworkshops.com/store/QqeJQL4U

Just click the play button.

This thread inspired me to model a ring and get it printed on a form 2 machine and cast in silver. I’m new to the casting process etc as i usually make game assets. My question is what material shall I get my ring printed in? Can I make copies of my printed plastic? Or would it be better to print in a castable resin/wax, then cast in sliver and then make a mold of the silver ring?

thanks for you advice mate. i love you jewellery designs!

thank you

if you are creating a master part you can print it in plastic spend the time clean it up and them make a mold.

if you are creating one piece you will obviously need the castable wax.

Hej Tomas

the large piece printed? Could that be printed in bright colours?

and is this print machine owner open to work from us?

Can you let us know?

P.S. Thank you for sharing your developments. Admirable.

The 3D Printing Bureau Service (FORM 2) i’m using have mentioned the details in my ring design will show up properly in castable resin but not plastic. Printing many castable resin copies is obviously too expensive. Can I get them to grow a copy in castble resin and then cast it in silver or metal or a plastic and make a mold for one of those? Which plastic keeps the same details as castable resin on the form 2. do you know? and can i make molds myself from the 3d print thats in plastic?

thanks for your help

all the best Montana

Barnacles - i have asked them, I would assume so but i always ask before i post on a public forum. so an answer will come soon

montana2008 - yes you can print the plastic clean it and make a production mold from the plastic. in fact thats how i plan to use it for the most part.

and fresh from the casting this morning

Metalphysics are true badasses

i give you the Noguchi homage table in bronze.

ooooooooooooooooooohhhhhhhhh

sooooooooooooooooooooooooooo excited to see it finished

Attachments

Wow Tomas

This is absolutely insane. That casting looks awesome, and so clean. You sculpt really comes to its right on such a big object, amazing. Fits very well with your style.

That print must have cost an arm and a leg tho!?

Oh and thanks for the heads up on the class, i think i will be joining in, would be very cool to talk to you again.

yes it would … i enjoy the things you make

yeah not going to be a cheap piece  the first one is the one that costs an arm and a leg … we have a mold so they should get cheaper as we make the second one

the first one is the one that costs an arm and a leg … we have a mold so they should get cheaper as we make the second one

have to get the patina on it and then the glass and ill know the bottom line on cost

yeah the grow cost … lets just hope we sell enough of them that “Amortization” is a real concept. lol