Love the photos of the WIP’s…

It’s so awesome to see a 3D model turn into a statue, technology is so amazing these days.

Very nice work, must be a great feeling to see it physically before you.

Amazing post, the process… everything. Thank you.

A dream comes true. The most important.

I love it! Turned out great!

FANTASTIC!!!

Should go Top Row if it hasn’t already.

Very nice work!

How do you print such a great model? Can you tell me what you use what kind of printer?

Really nice!

Thank you for sharing the process!

@Popkusa:

Thank you. Once the exhibition dates are set, I’ll invite you to see the physical one for sure

@asecbrush

Glad you like this piece. It’s a fun journey for this work from Digital to Physical world.

Glad you like this piece. It’s a fun journey for this work from Digital to Physical world.

@pygmalion:

It’s exhilarating trying to make this piece into Bronze. If our project goes well, I’d like to propose for a large scale Bronze park…(A fantasy park filled with ZBrush works  )

)

@SpiritDreamer:

Thank you for your kind comments. During the course of creating this, I was trying to capture the moments as I go through the process. Will post some more photos on the prints and stuff soon.

@Derek Frenzo

Thank you! In fact…it’s quite an experience for me as we were in the middle of casting, there was a huge flooding and pretty much put the foundry under the water for a good full month. The art exhibition’s then postponed to this year instead.

@Bloodflyte

Indeed, I really like the marriage between the new technology such as ZBrush and 3D printing / CNC with tradtional medium. The two actually play well together.

@michalis

Glad you like it. As stated, the first time the model’s printed out, it’s like you delivering a baby to this world. Your creation that can be touched and rubbed

@nickz

Thank you bro  Really appreciate your view here

Really appreciate your view here

@EricShawn

Million thanks. In fact, the quality of Bronze do count toward the final product. As I chose everdur / Silicon Bronze as the medium, it allowed a pretty solid/fine cast. In fact, the foundry also provide Stainless Steel as one of the newer casting mediums (Which does look futuristic and suitable for a smoothed objects/sculptures)

@nfuchs

Thank you, glad to be able to contribute to this great community  And glad you like it.

And glad you like it.

It’s a lot of trials and errors …and I’m still new to this printing thing. Sometimes you might get errors from mesh not water tight and such like this very early test on the hand.

@akatsuki

Thank you very much. For the print, I in fact did so many test prints on various machines. Each machine do have its pros and cons. If you’d like I can share you some findings.

The good thing about Bangkok is there are quite a few companies here carrying many types of 3D printers. The ones I have tested are(Please note that the manufacturers of each machine do have variety of product range, hence this may not apply to all the printers ):

1. Stratasys Dimension (http://www.stratasys.com/Products/3D-Printers.aspx) This one utilizes FDM(fdm fused deposition modeling) that lay a thin layer of ABS(Plastic) at a time. The result is quite detail print out but with stratified lines. You can smooth out a bit by using Acetone (Nail polish) but that could also take away your modeling details. The good thing about this is the end 3d print’s very strong.

You may check out their presentation here

2. 3DSystems V-Flash (http://printin3d.com/3d-printers/v-flash-personal-3d-printer)This one I was very fortunate as my project’s sponsored in parts by Office of Contemporary Art And Culture, Ministry Of Culture, Thailand and Comgraph (one of the printer’s local distributors). It uses Film Transfer Imaging (FTI) technology… And leaving model smoother without having to smooth manually as much. (I will post more images from this soon, need to take the photos out of my camera)

3. Objet 24 (http://www.objet.com/)

This one employs PhotoPolymer technology which yields quite a good result holding great details. While the details hold great, it’s less durable than ABS. And in the heat of Bangkok, a thin layer of print can be warped as well. (But very impressive print output quality) The higher models of this brand also promise a higher / refined output. I think (Personally), if it’s not too cost prohibitive I’d print with this system. But again the cost is quite high (At least for a poor artist like me)

4. ZCorp (http://www.zcorp.com/en/Products/3D-Printers/ZPrinter-250/spage.aspx)

I think they are now a part of 3DSystems? This technology is quite unique as it allows color printing that can output 24-bit color range. The model I received when I earned the Pixologic Hero contest was printed with this technology. While it’s great at outputting color, it tends to be a bit brittle. And my Bronze piece will need to be patina anyway, hence I did not choose this route.

5. Foam utilizing CNC 4 Axis Machine

This method uses Computer Numerical Control (CNC) to cut through solid specially dense styrofoam. This method I use to output large scale sculpture and apply Hot Wax onto the surface to refine the surface details. The result of the initial output’s not as detailed as the rest 4 above but at 24", it can be output in 2 hours time. Allowing me to get hands on with the sculpture fast.

Sample vids of this technology

and with 5-Axis

I hope this is helpful to you, should you have any further question, please do let me know. I’ll be more than happy to answer.

Snake! Great breakdown and great sculpt.

Great work, love the contrast in feel between the 3d version and the 2d interpretation, really lovely.

nice sculpt and cross medium piece. Love it :))

HI ,

SolidSnakexxx

Excellent work very good concept  .Can you please provide me some information about 3d prints how they are done and where they are done.

.Can you please provide me some information about 3d prints how they are done and where they are done.

Amazing!!!

I love all the pictures and the step by step how you made this!

Wow!!! What an awesome piece!!! Beautiful results -> thanks so much for the in depth sharing of your workflow -> (btw:Would be super if you could record a turntable of the actual piece)

(btw:Would be super if you could record a turntable of the actual piece) small_orange_diamond

small_orange_diamond small_orange_diamond

small_orange_diamond small_orange_diamond

small_orange_diamond small_orange_diamond

small_orange_diamond

Excellent work and very useful information about 3D printing. The technique is expensive, then I certainly will watch its development.

beautiful work. Love it!

Totally amazing! Thank you for sharing the process and breakdown, and all the other info. I find this really super exciting, realizing real life sculptures and works like this via digital sculpting. Feel free to add more pics and info  !

!

Congratulations on what you’ve accomplished and having you and your girlfriends work on public display.

Awesome!Thanks for the breakdown and the videos, and all the text, very interesting read!  small_orange_diamond

small_orange_diamond

I agree with Geert a turnable would be nice, and congratz on top row, well deserved!

Amazing! Im greatly Inspired by your Masterpiece! A true Authentic, timeless piece!

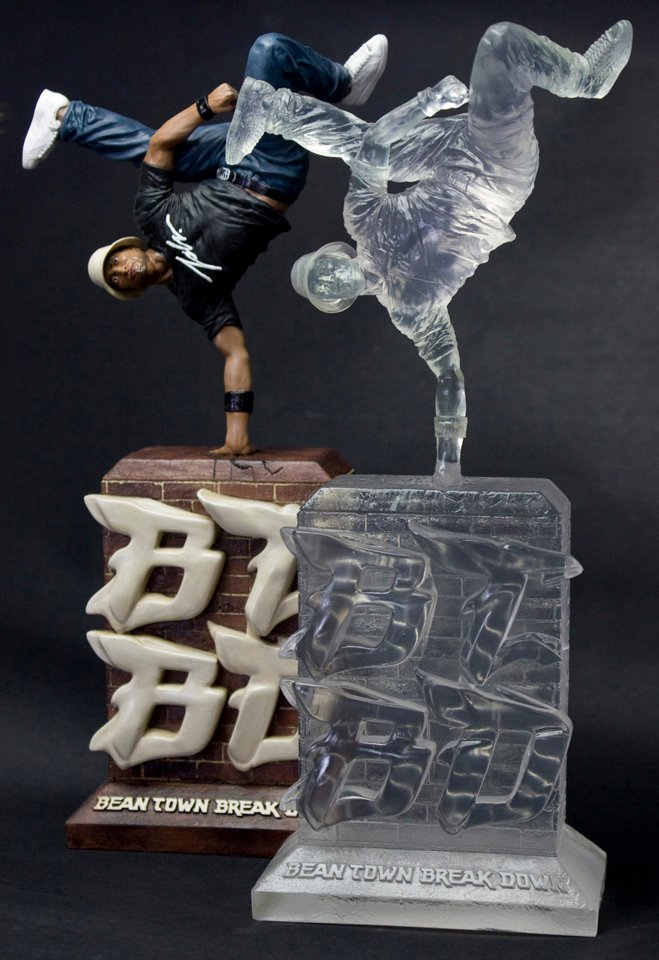

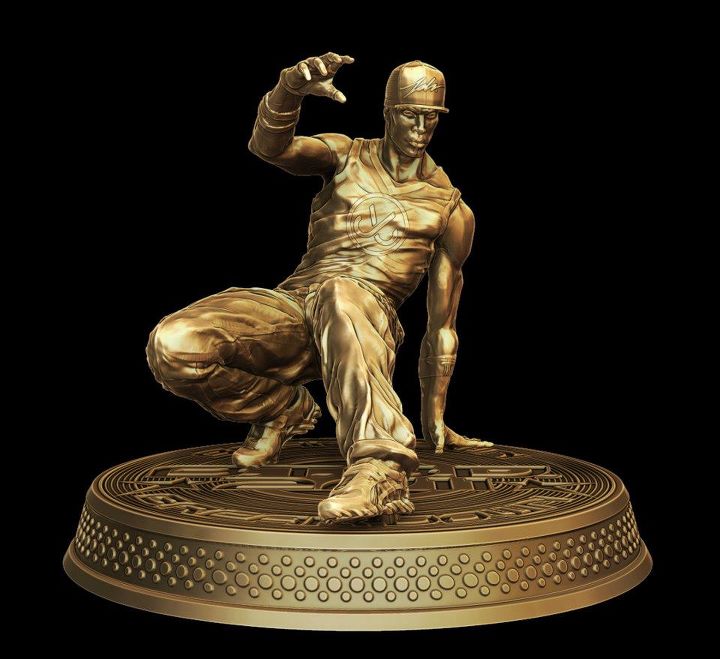

I had the fortune have sculpted & printed 2 Trophy Sculpts for an annual B BOY (Breakdancing) Competition

Picture This, a Break Dancing BATTLE Competition: a room full of passionate Hardcore dancers & like hearted fans going Head to Head to WIN a Trophy and $ prize! The Excitement and Electric Energy of Young Hard-Core dancers, Competing with ALL they GOT and Winning! After Years of hard work, blood sweat & Fears-faced (like some of us ZB artists), Just Pumped w/ Adrenaline & JOY after Positively Battling it out! The results were Good & Bad…but, in the end GREAT!

-

The first one was unfort. casted in a delicate plaster (on account of a rush job (?) . As you may expect, many of them where Damaged before i opened the shipping box…UGH, …3-4 out of 10…and who knows how many Trophies Broke, after the Excitement of the winners: Jumping For Joy, Hugging, Wildly Bursting with Joy, Celebrating their wins! …All with Trophy in hand! Yikes…We learned allot from that run.

-

The second, we ordered the paintable PVC type (?) Plastic material. This was Perfect for the project. (durable) considering the use of the Trophy: Again. Picture a room full of Young Passion-Fueled Dancers. After Winning, their blood sweat & Fears-faced! Pumped w/ Adrenaline after a HardCore BBOY/ Break Dance Battle! a Wild Celebration of their Triumph. lol! Thankfully None broke!

I am very interested in getting a Bronze cast for this years event. Do you recommend a serves source? Thanks for reading & posting such INSPIRING WORK!

WITH All respect due, Im did not intend to leach exposure off your Thread (well kinda) BUT, you can delete this if you’ld like.Thanks. Bless you, for blessing us with Motivation and Inspiration!

BLife

http://www.zbrushcentral.com/zbc-thread-gallery.php?tid=162470

I just saw all the pages in this Wonderful informative thread. Thanks you greatly for all your help. Vital resources shared! Amazing results!

First of all thank you all…for reading my post and really honored to be placed in the Top section.

@N8:

Thank you for your kind comment. Glad you like it.

@Ivo Diependaal:

Thank you. We deliberately chose 2 opposing color themes; hotter tone for the Bronze and the cooler one for the painting. Glad you like them.

@johnchen:

Thank you. There will be more in the series. I’ll post more progress here for certain.

@abhi_down:

As stated in my earlier post, there are many different types of 3D printing machines and services. So far I’ve had a chance to get my models printed by:

1. Offload Studio (http://www.offloadstudios.com/) as using the ZCorp technology

2. Comgraph (http://www.comgraph.co.th/rapidmfg.php)

A local Thai company that sponsored me for the project. This one uses V-Flash (3DSystems)

Another Local Thai company which I was given an honor to do a test print. Was testing with a Dimension printer (result material is ABS plastic).

- Another local company which I had a chance to see it printed using Objet. You cna also use http://www.shapeways.com/materials/ with material “White Detial” for this as well.

- Foam CNC, Also used a local company, 3D Rapide, for large scale statue.

@chrono1081:

Glad you like my step-by-step presentation as some of my students were asking me to give a quick run down on the process.

@spacemonkeydr:

Thank you. Indeed, the Patina work on Bronze by itself is very satisfying step.

@Etcher:

Thanks mate. I did record the physical turn, it’s in my camera as well. Will post that when I have a chance to jack it into my computer

@rulonis:

Thank you, and you are right… the technology is getting better and better. Hopefully the cost will decrease over time. In fact there are some Pre-assembled and Home-assembled 3D Printers out there. You could print the form with these but not as refined.

You may also want to check out

1. Up! 3D Printer (http://pp3dp.com/) The system is around $2690

2. Cubify (http://cubify.com/info/cloud_3d_print.aspx) Cloud 3D Print Service and Machine…sells for about $1300

These are based off the OpenSource 3D Print RepRap (Read here for more info: http://reprap.org/wiki/RepRap)

@Crevasse:

Thanks!

@fattkid:

Thank you. Prior to doing this method, I was spending nearly half a year researching/ reading up, and going around checking and testing various printing technology. I think some of the printing technology is really good…but still cost prohibitive. I think not so far from now, 3D Printing could be a household technology like a toaster.

@Santis:

Thank you. I guess many would want to know about this as I were before I started my journey. Glad I could share this.

@brianlife:

Thank you very much. You Trophies look great as well. Really enjoy reading your post. I think doing these kind of things would still take some risks as there are many steps involved… Not to mention many factors contributing to the final products like the method of printing, materials, and the method used for mass producing. But all-in-all we must agree it’s a joy to be able to grab your creation physically

As for the Bronze, It depends on where you reside or if you can take a trip to Thailand, I could show you my foundry of choice. Of which some of the world’s famous Bronze artists also utilize their service. Again, I think ZBrushCentral is more than just a ZBrush forum…I do come here once or twice a day to get myself inspired. And once in awhile, I’m so happy I could give back to the community.