Hey all,

I need some advice for this model that I hope to output to a 3D printer.

Two questions.

#1

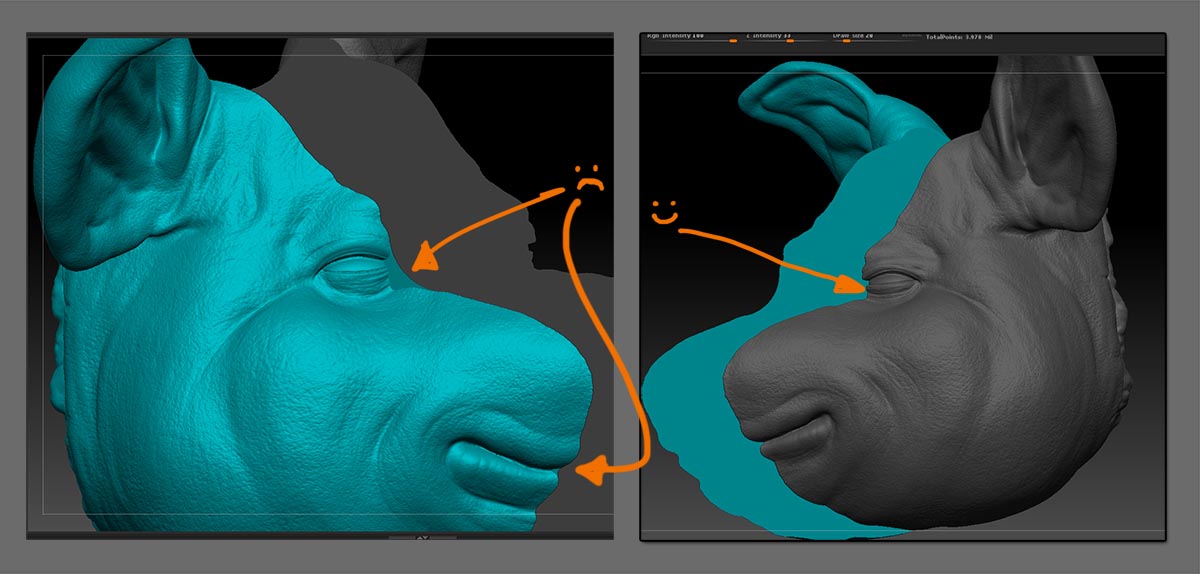

How can I avoid the faces shown in the screenshot when I close holes on open subtools that have overhangs? Oddly enough it only happens on one side of the face. They aren’t perfectly symmetrical, but close.

To ‘fix’ the problem I’ve been isolating the newly formed cap (via polygroups) and selecting/hiding/deleting the offending faces. I’m then going back and patching it up with the CurveBridge brush. It’s slow and doesn’t give the cleanest results.

#2

I’ve missed a few of the smaller overhangs and have since unified polygroups, so my fix technique would be tricky.

I plan to 3D print these meshes. Were I to leave the ‘spanning’ faces, is it likely the printer will reject the .STL, or will it print anyway? I realize they are so thin they might not even print… I figure I can always trim those faces away when the print is complete, if they do manifest…

Any advice, perspectives, comments, are welcome.

Attachments