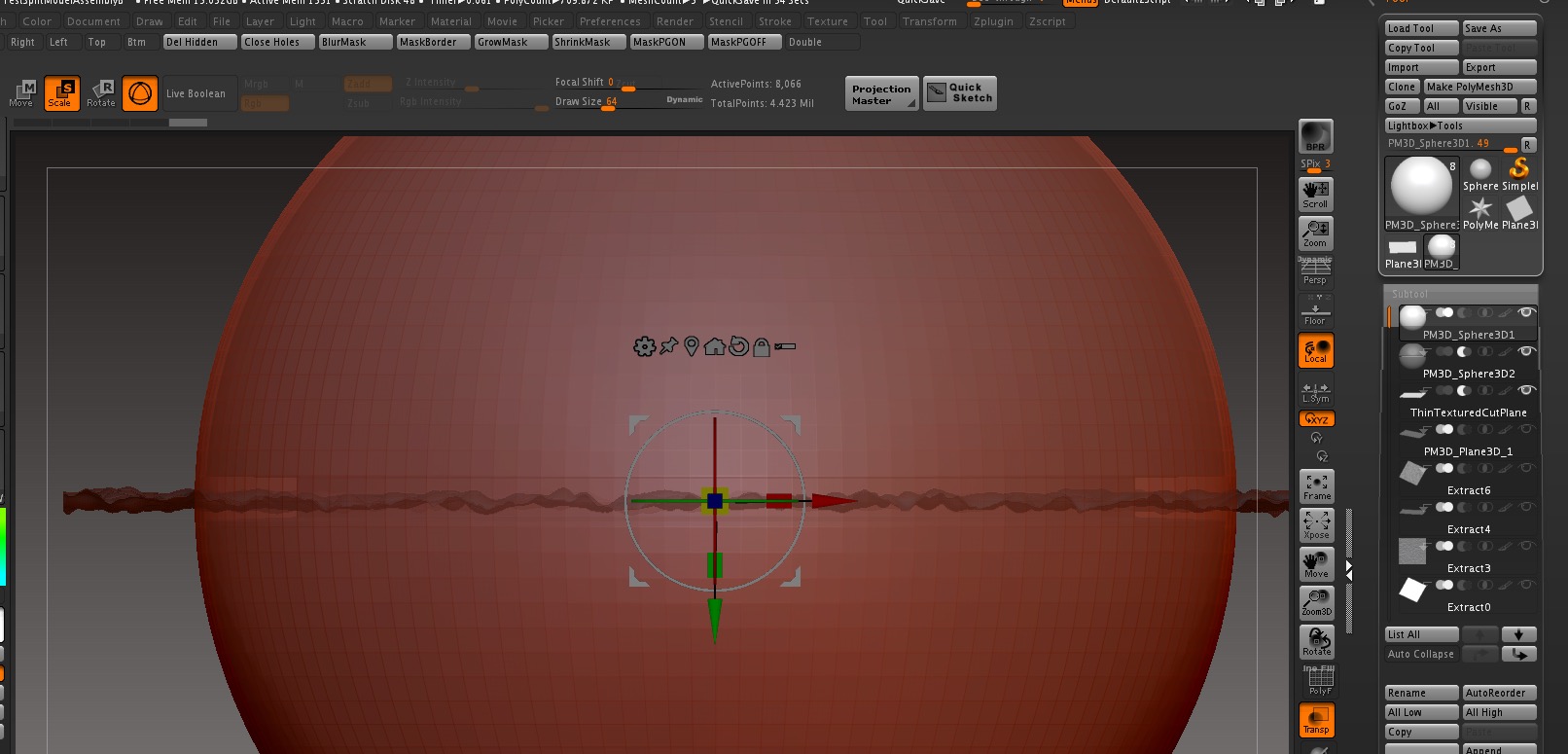

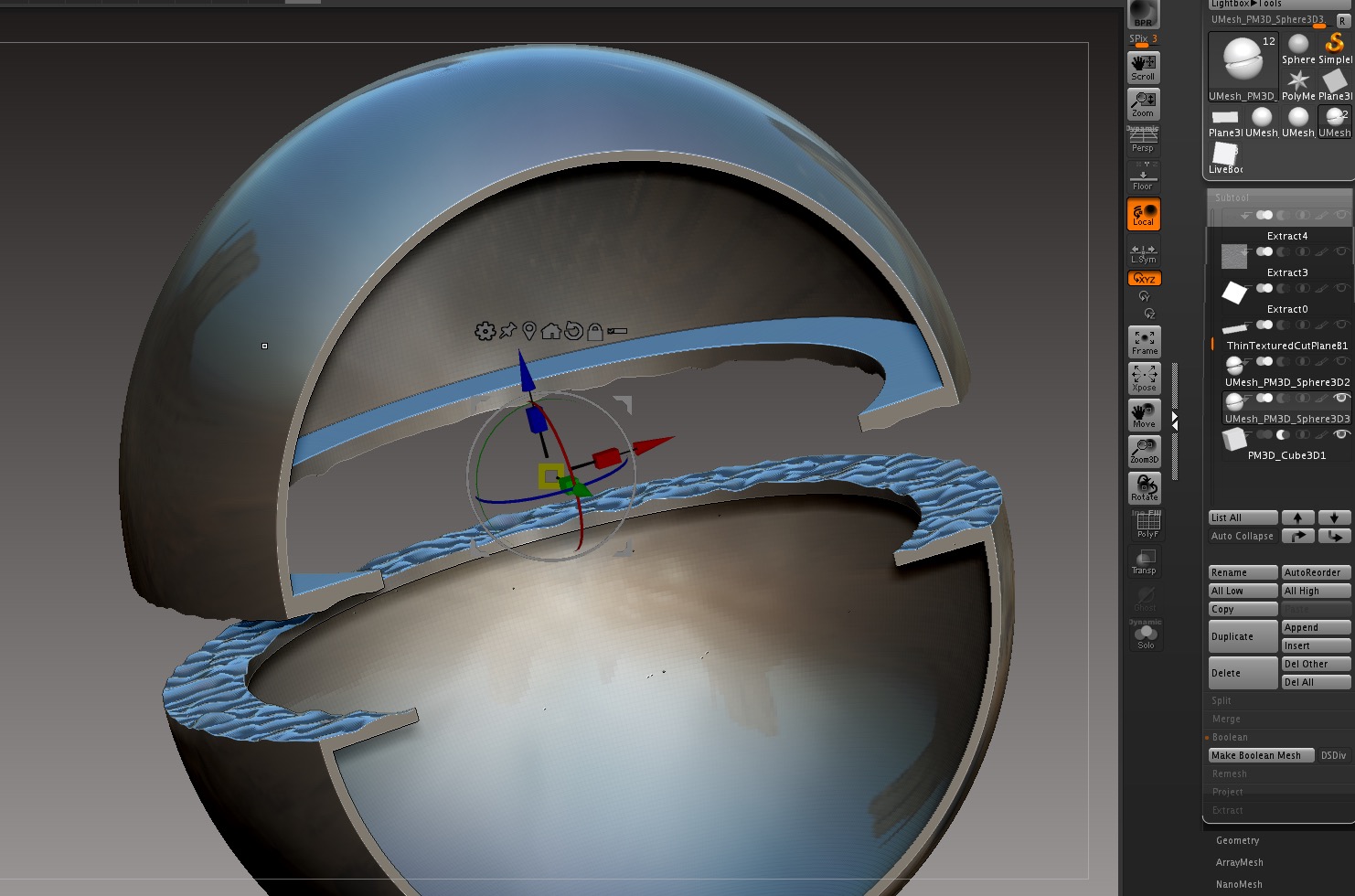

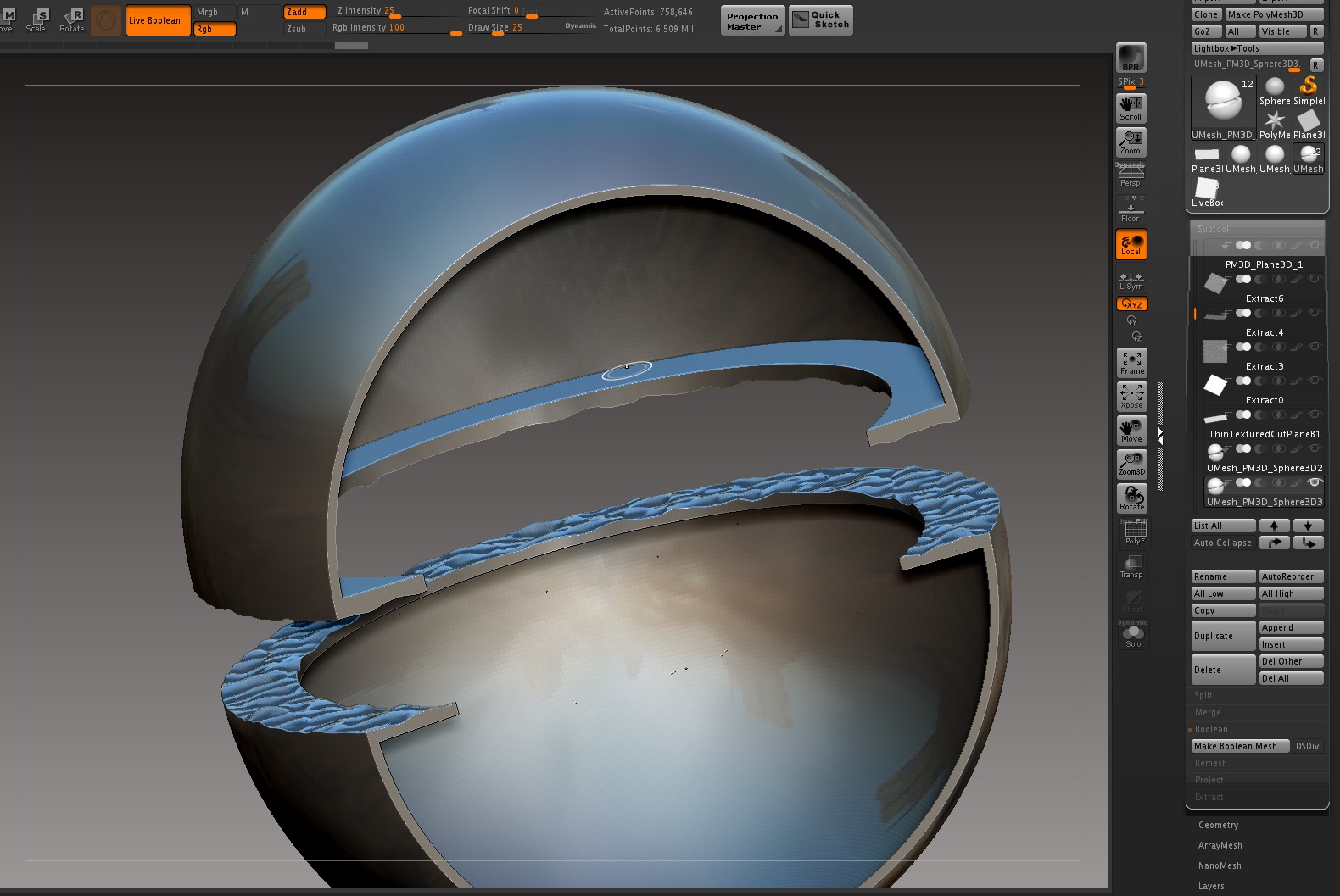

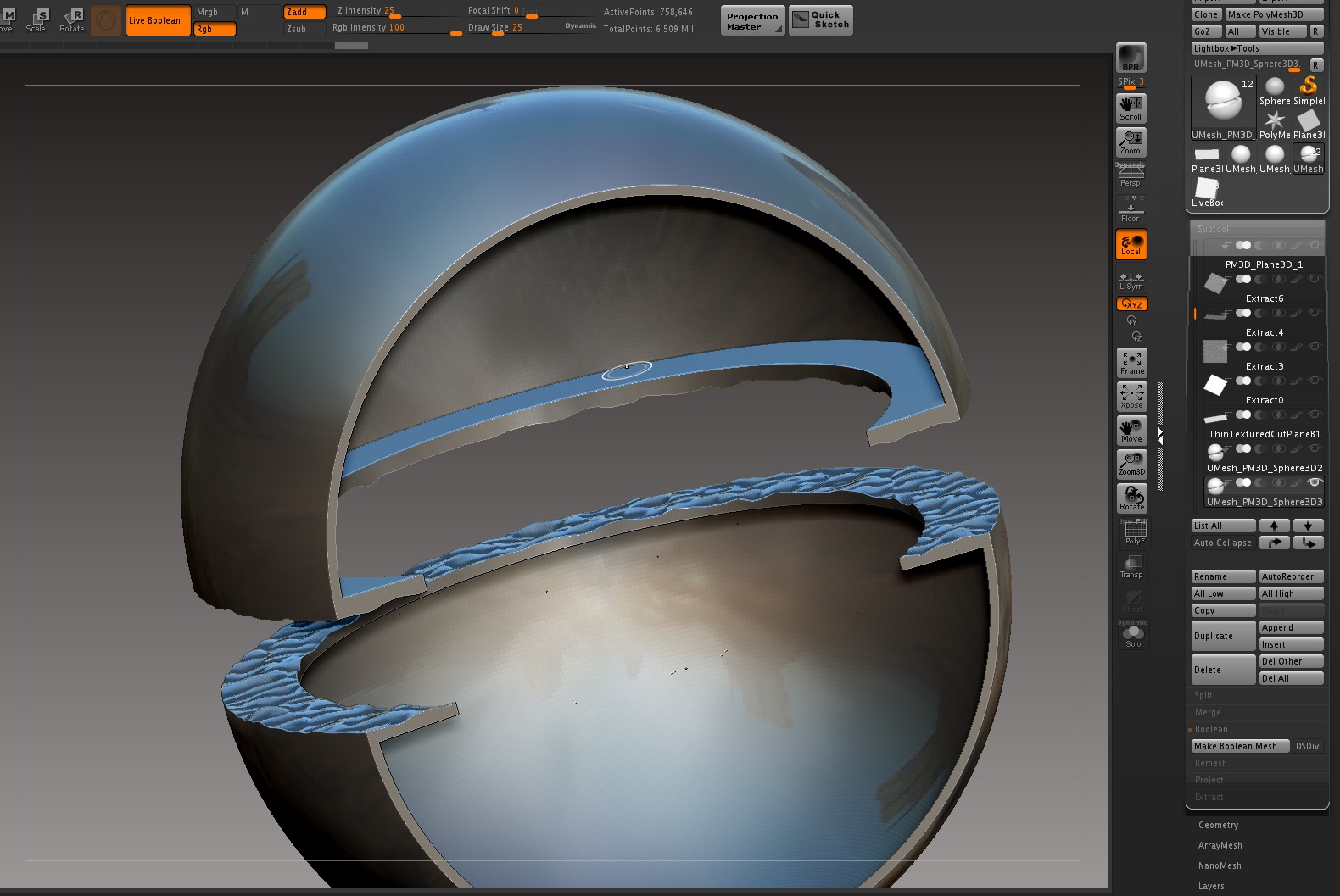

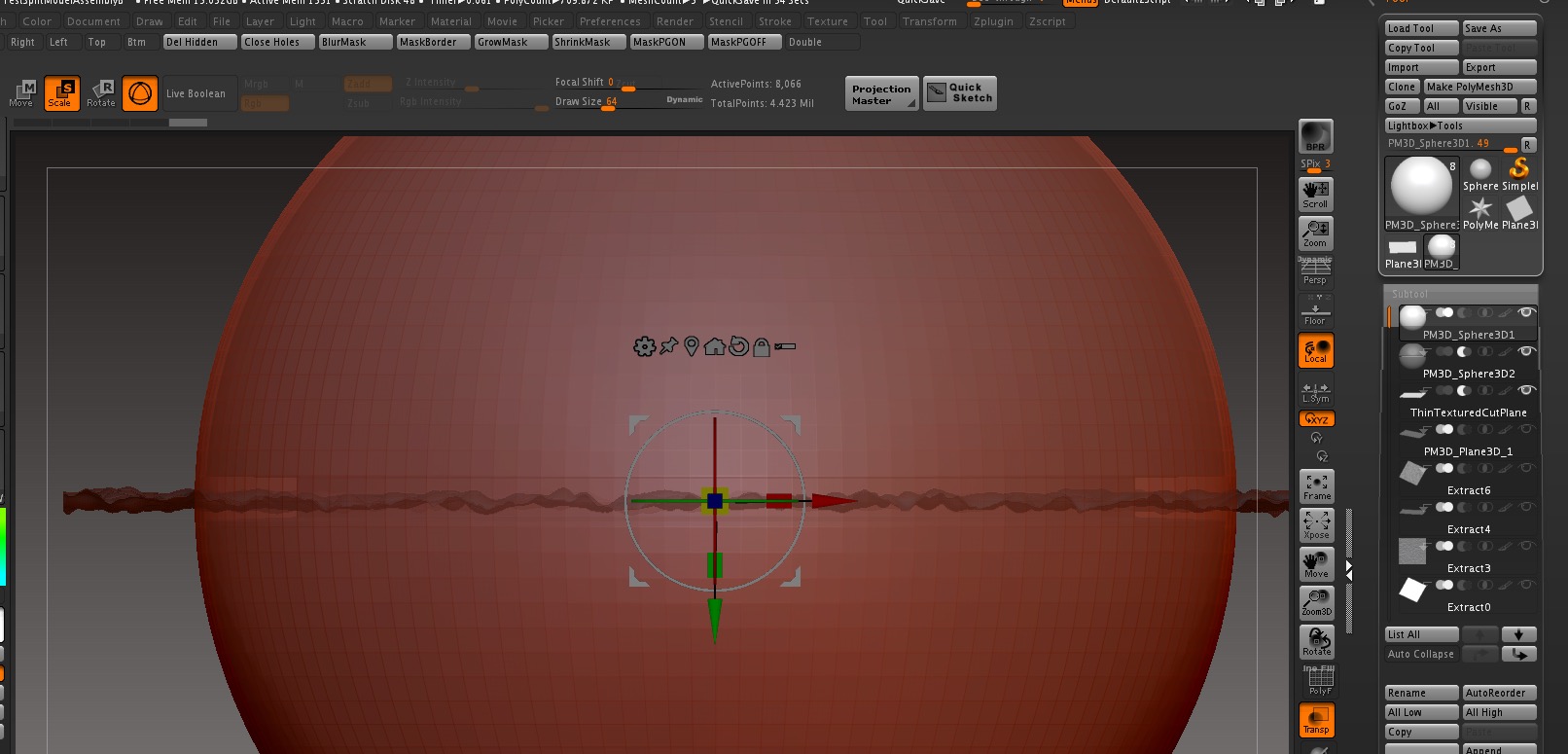

Any (boolean?) workflow suggestions for- slicing through a mesh, creating 2 parts

- each side of the resulting mesh having mating bumps or keys to help register the two halves after 3d printing.

I’d like to more easily chop up my models for 3d printing, and at the same time, create bumps or keys on both halves to assist in fitting the parts back together.

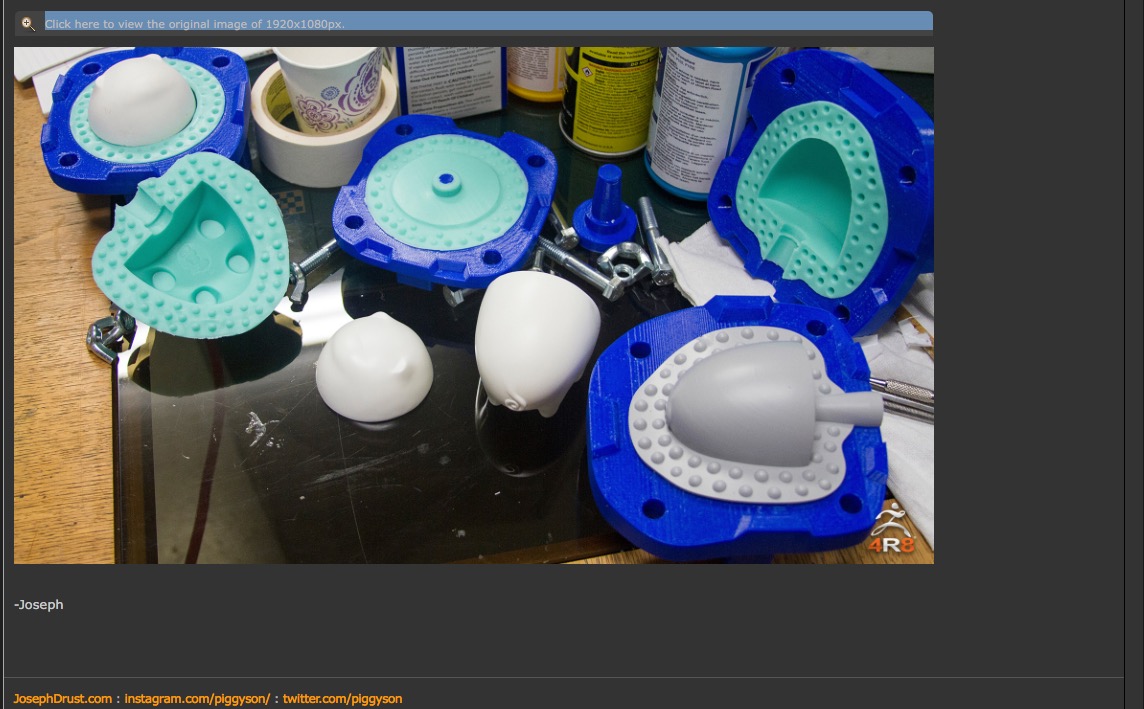

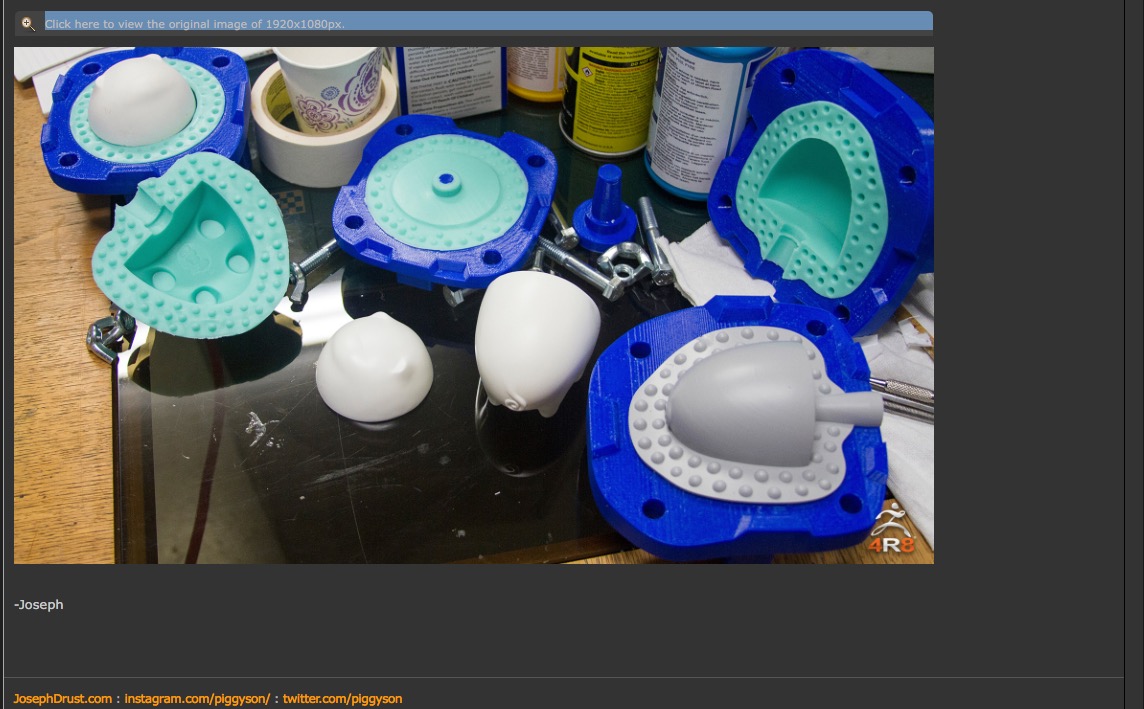

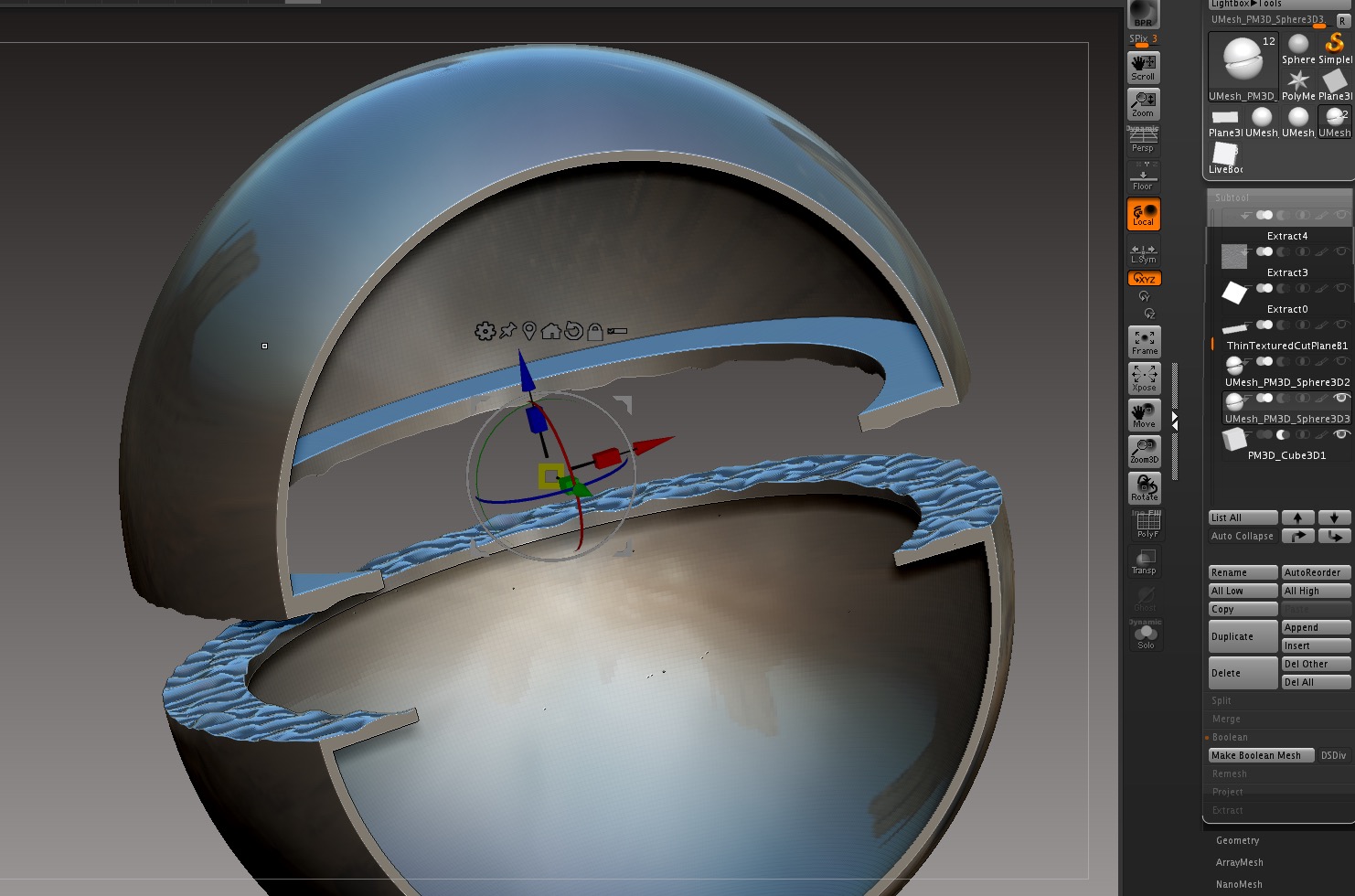

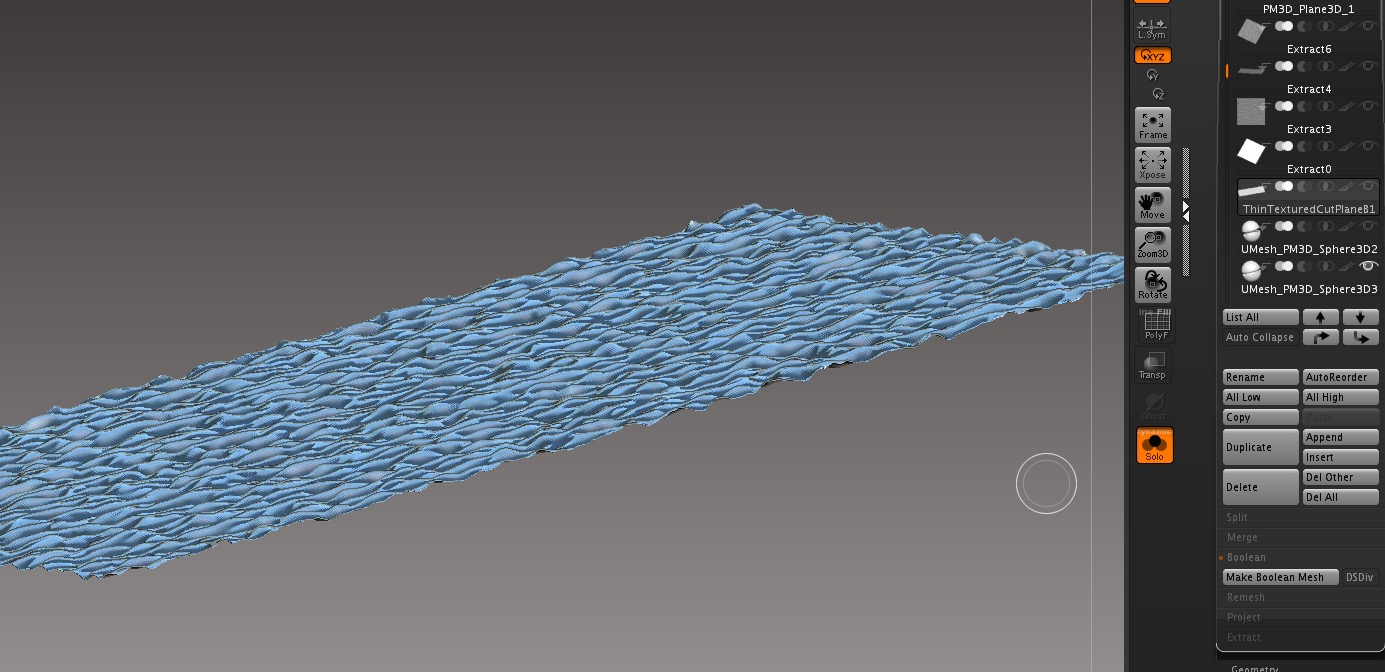

The image below is from Joseph Drust’s 4r8 demo where he is using hemispheres and irregular cuts as the keying features.

I assume it’s a pretty common practice used to break up models for 3d print.

I have a feeling that I am making this too difficult.

thanks!

Attachments