Hi Again,

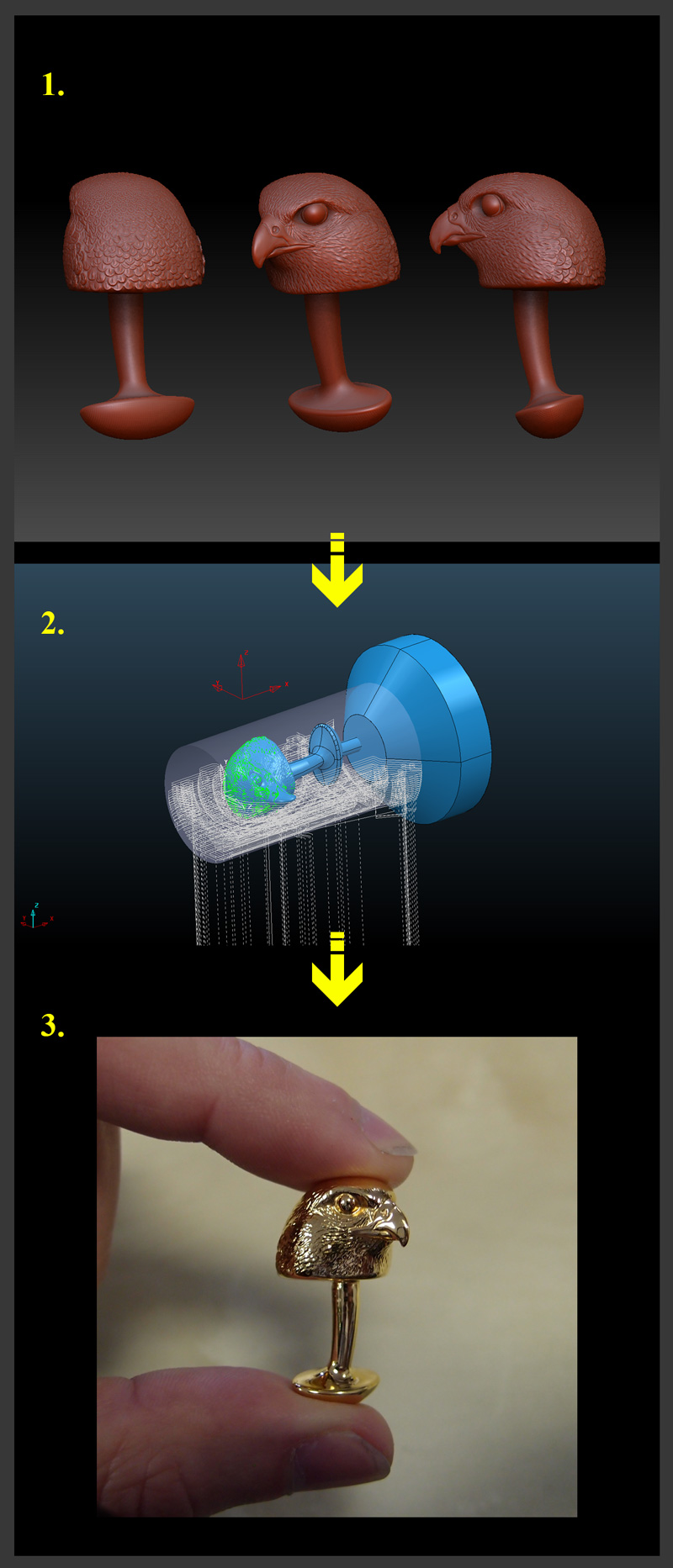

Some of you may find this interesting. A brief look at how I use ZBrush in the manufacturing world:

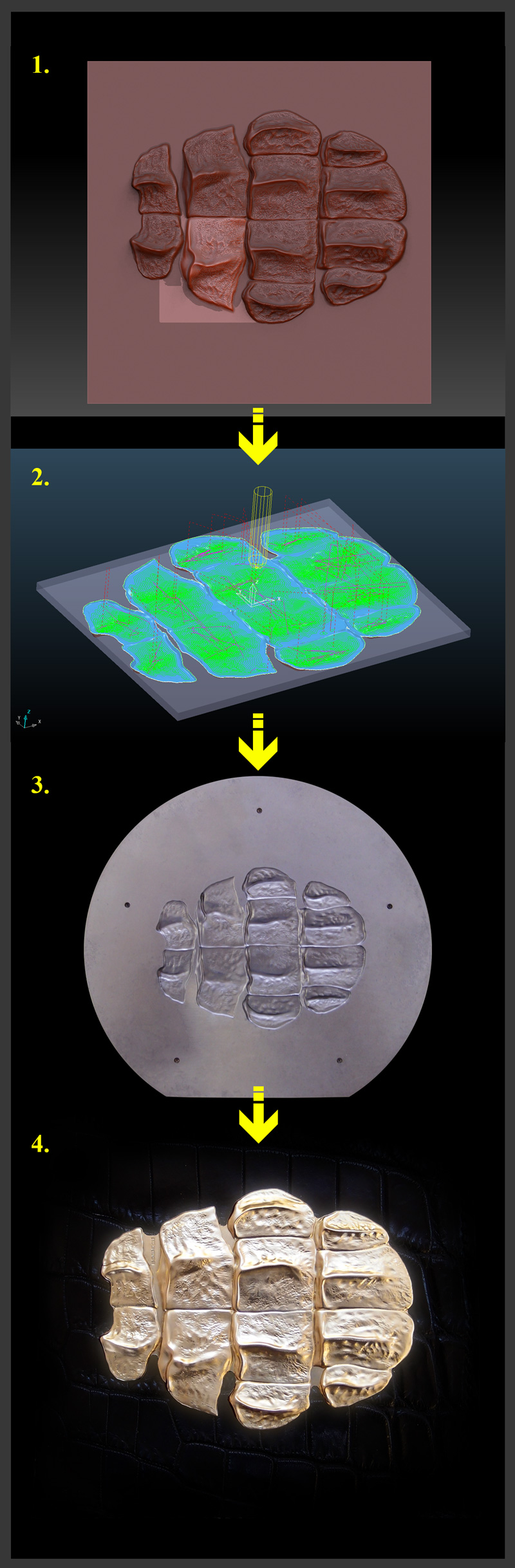

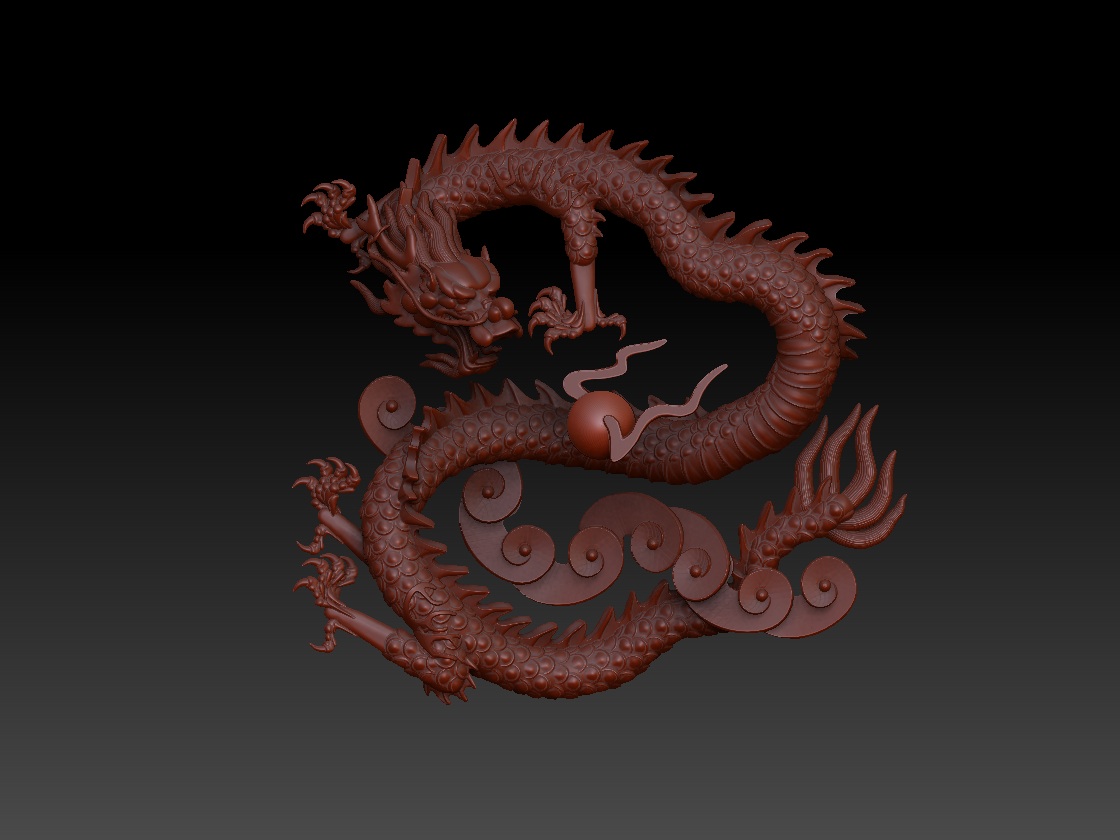

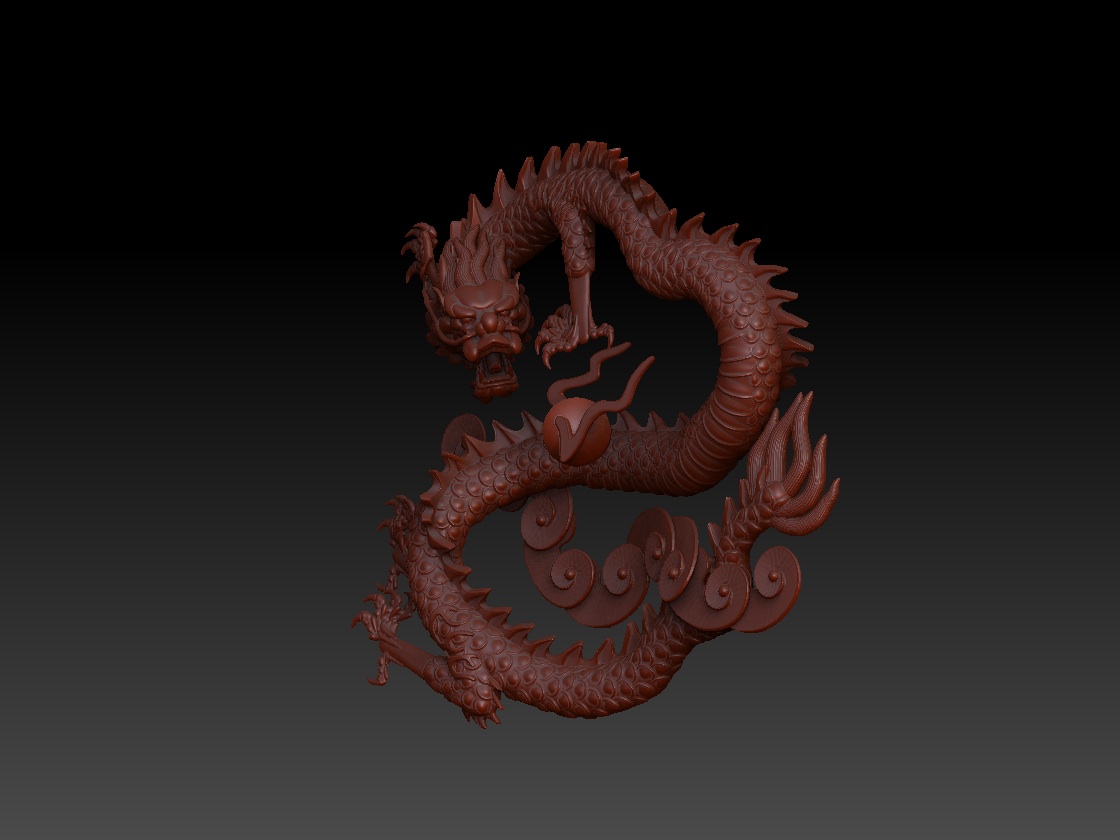

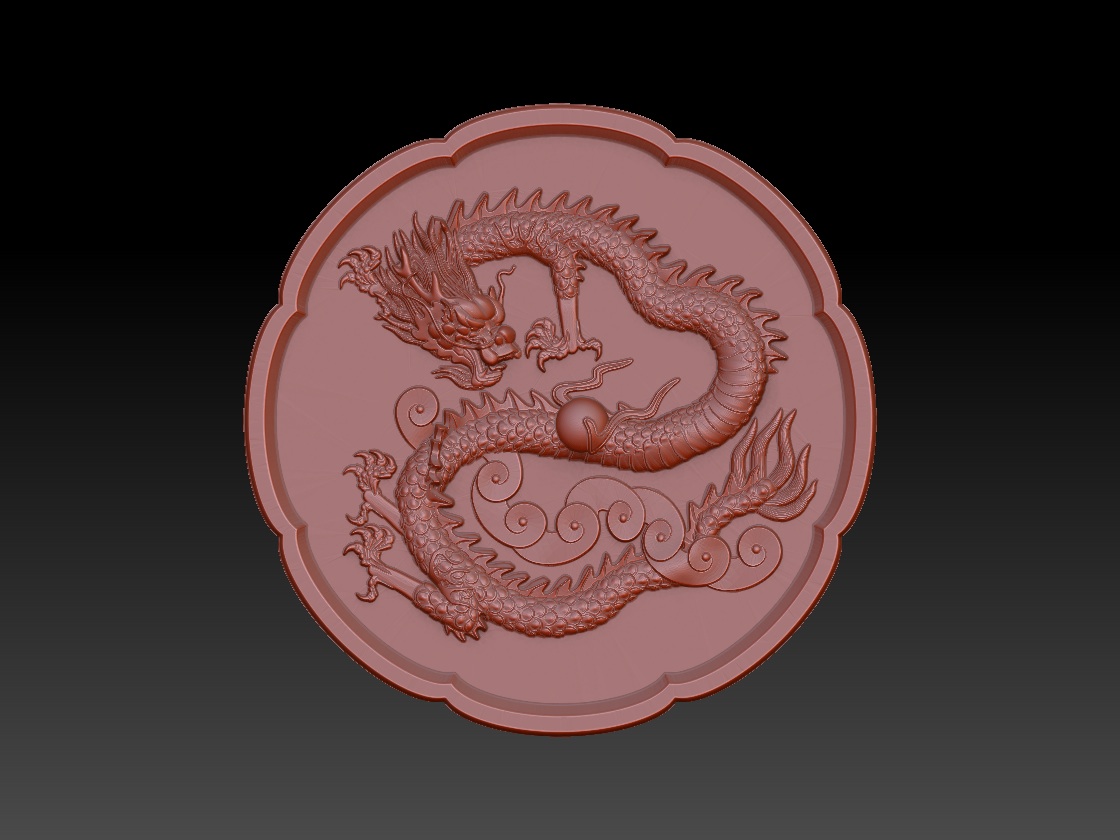

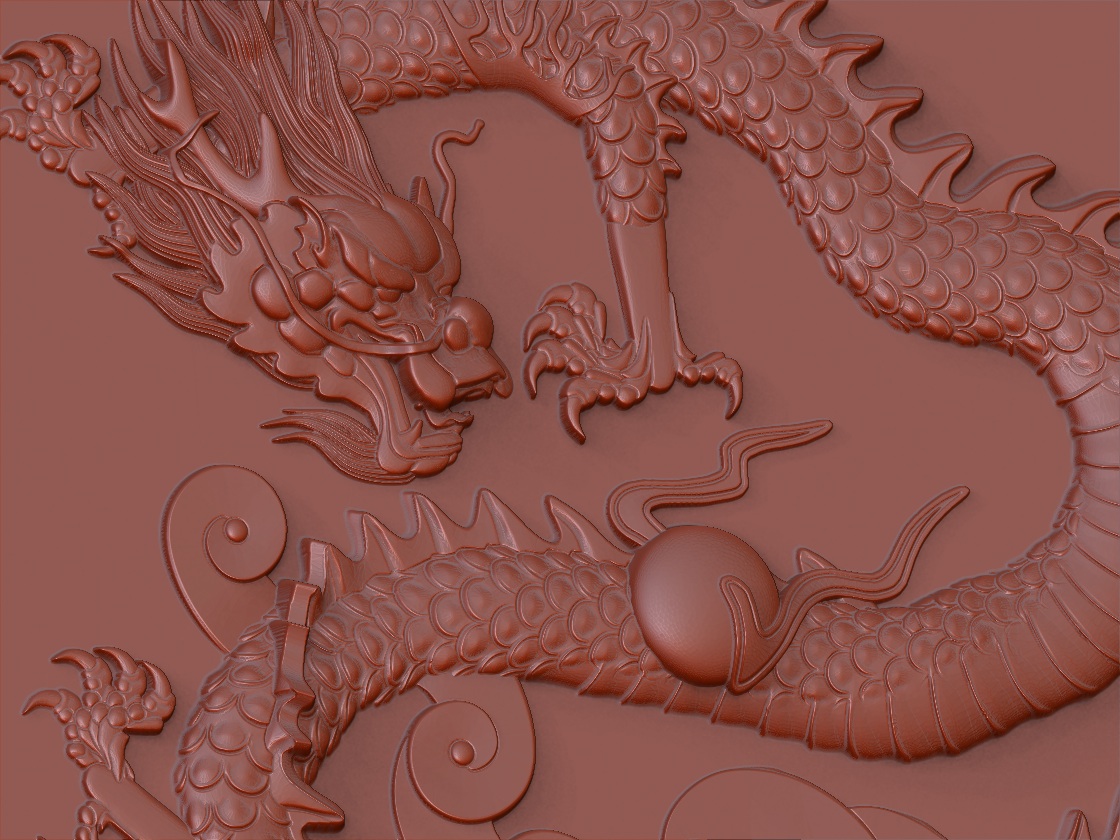

1. Sculpting of the ‘Crocodile Horn’:

Initially the sculpt was done as 1 complete bas relief, the results weren’t bad but not what I was looking for in terms of definition between the scales.

After several attempts breaking up each individual scale allowed far more freedom and movement.

ZProject was used to create 1 solid mesh which was then exported to Artcam for exact dimensions and draft angles.

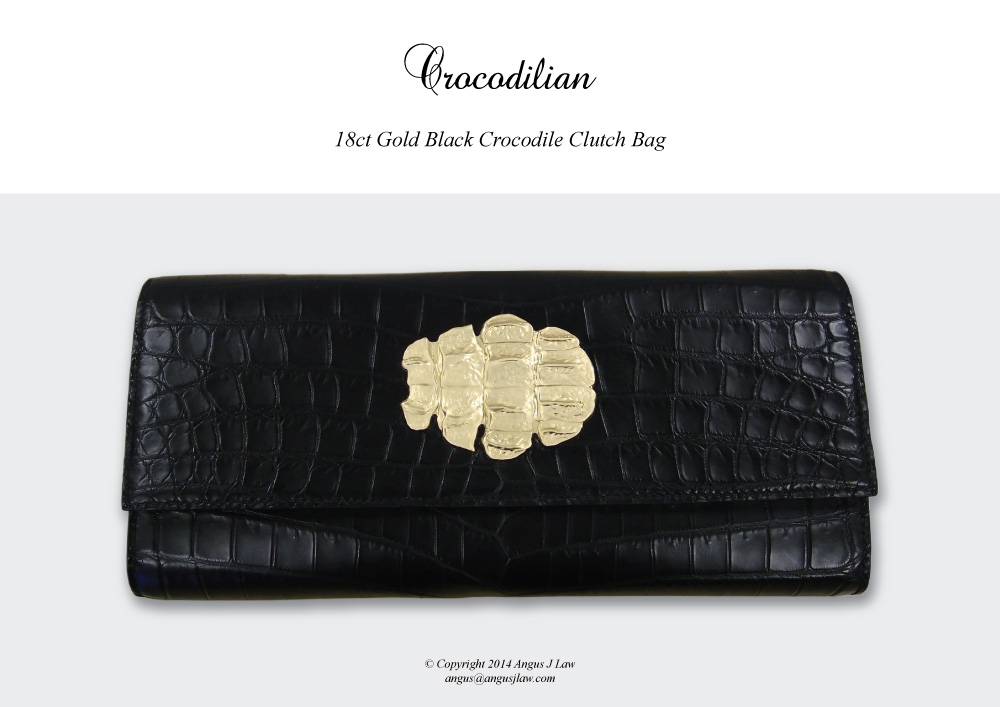

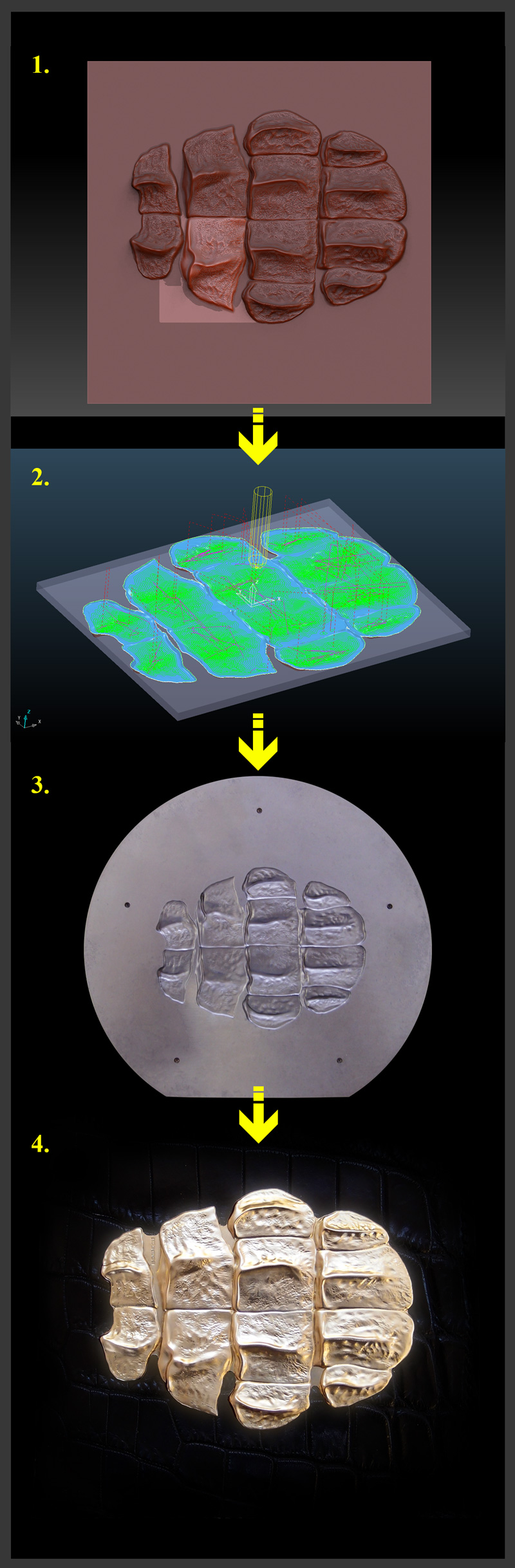

2. CNC Programming:

I’ve attached a screenshot of one of the roughing toolpaths used.

Machining in tool grade steel is no quick process; you go to fast, the cutter breaks; you use a cutter to small for the job, it breaks. Therefore you need to breakdown each process starting with largest cutter feasible and gradually work your way down in cutter size while increasing definition.

The final pass took over 12 hours to machine. Certainly worth the wait.

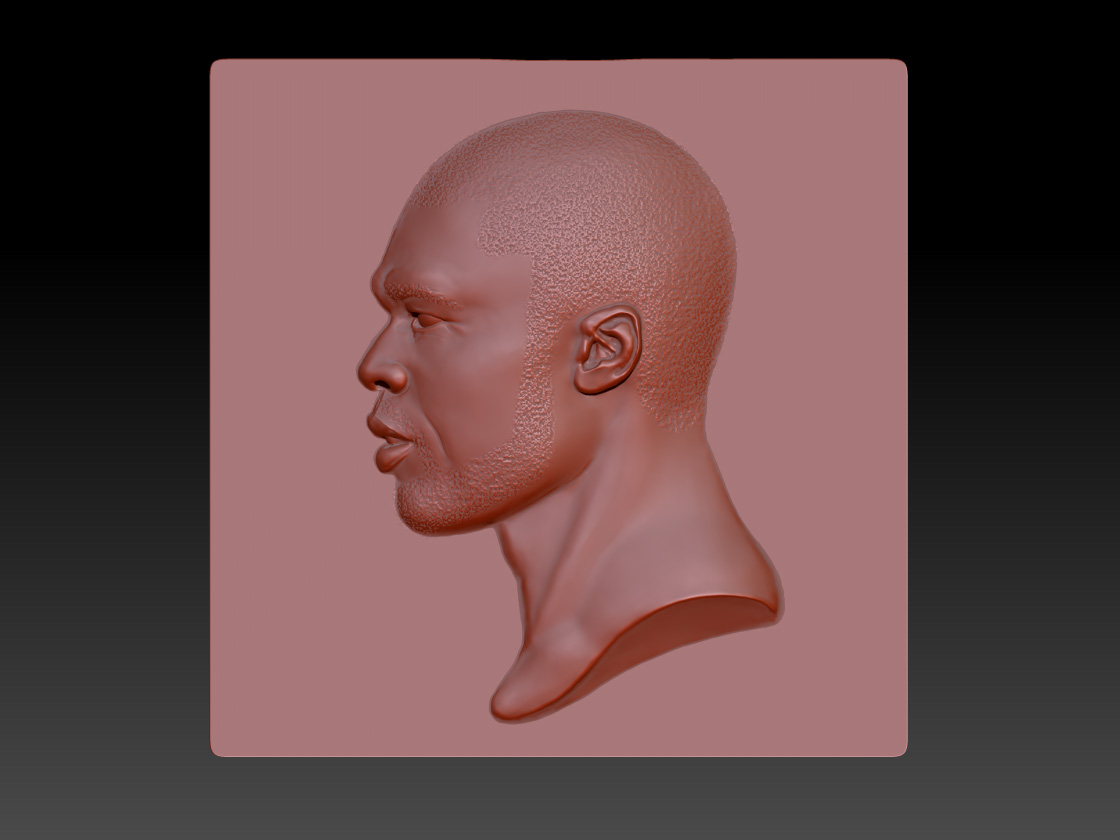

3. Working Tool / Die:

Quick photo of the finished tool. This is then placed in a coining press along with the required gold and stamped several times. We used over 360 tons on this piece.

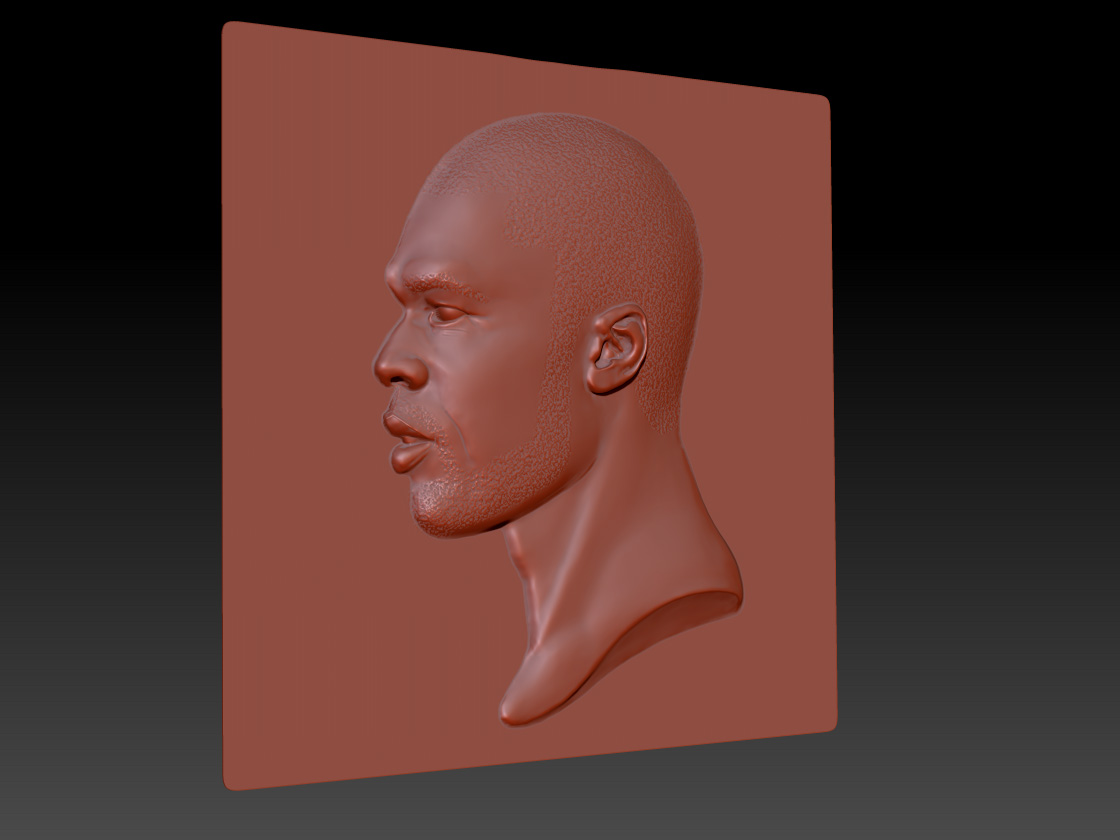

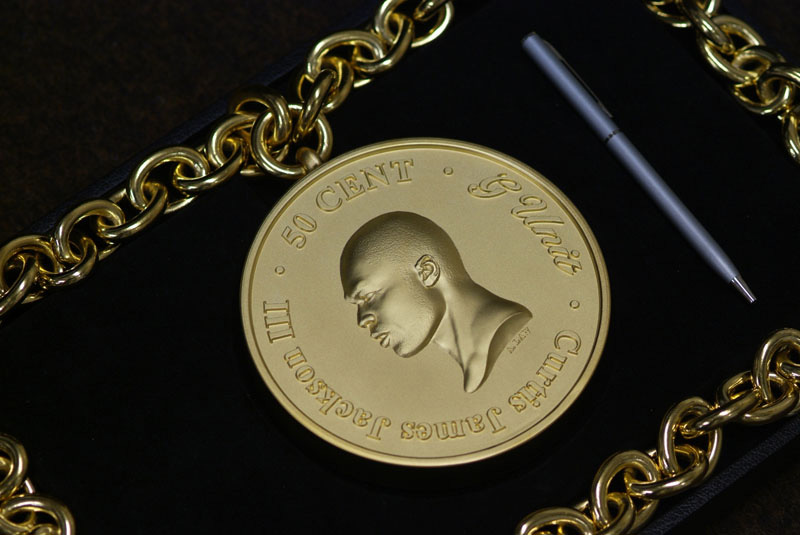

4. Finished Gold Piece:

Photograph of the finished struck piece in solid 18ct Gold.

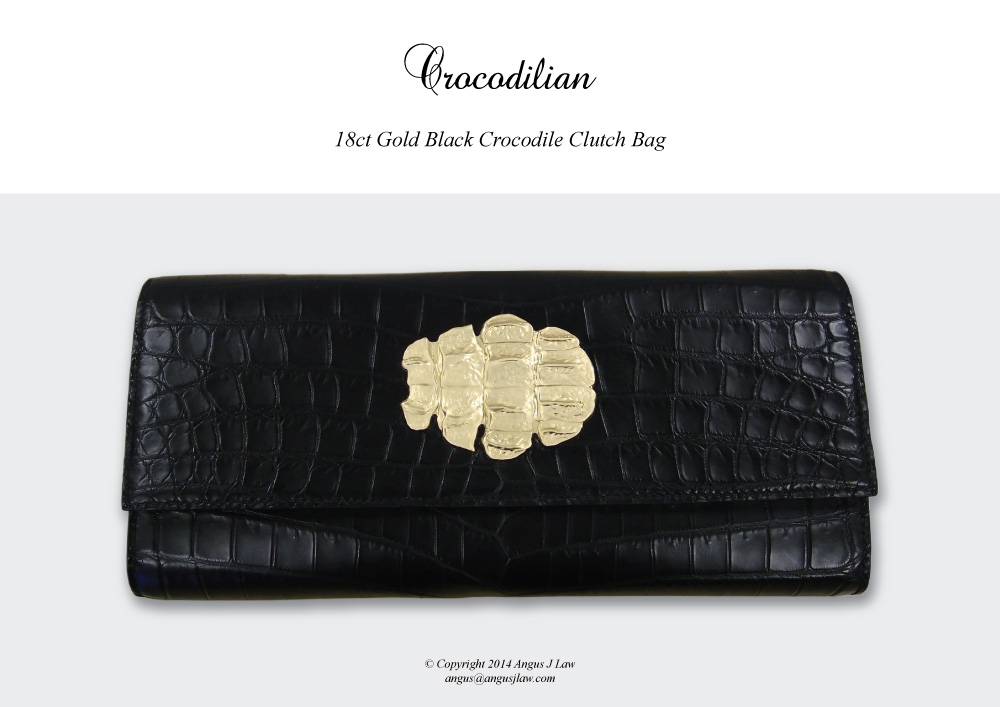

Finally I’ve attached a photograph of the finished article mounted onto Genuine Crocodile Leather.

Any questions please feel free to ask,