I am trying to hollow out my model to make 3d printing cheaper. Below is what i have tried. But i know there is a way to make an interior wall with a uniform width all throughout the interior. - But maybe not in zbrush.

Attempts at hollowing:

WAY1:subtract boolean

WAY2:manually

WAY3:extract

WAY4:re-topography

here is a link to the full conversation i had about hollowing a model. look 3/4 down – shanec102— for full descriptions of how i tried to hollow:

http://www.shapeways.com/forum/index.php?t=msg&goto=22371&&srch=zbrush+hollowing#msg_22371

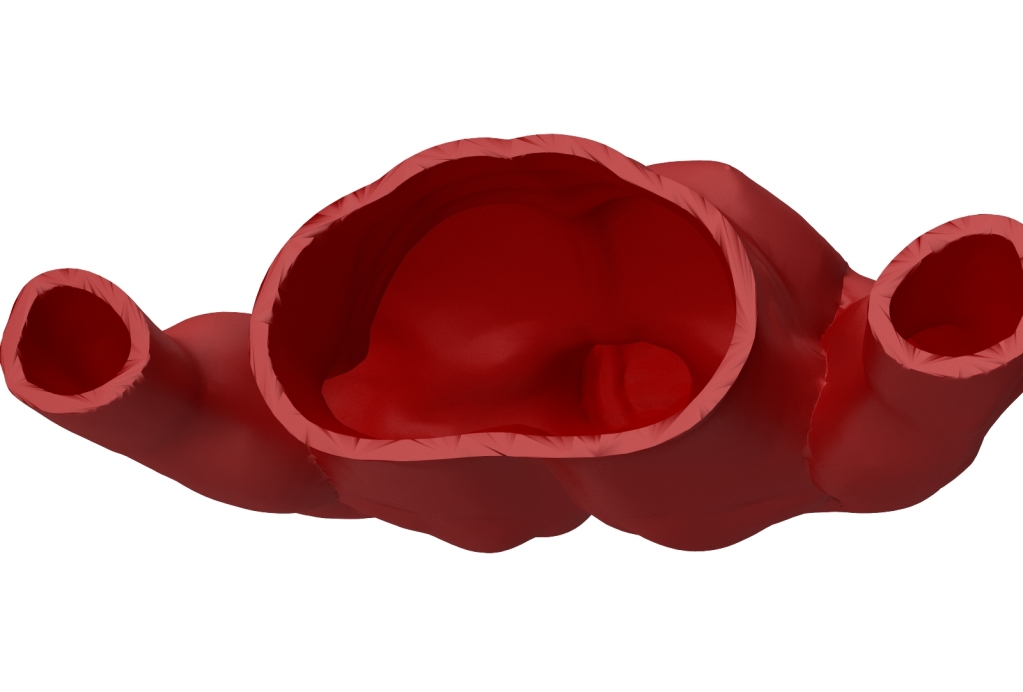

attached is a photo of a perfect uniform wall.

my question is how do i do that? If I can not do it in zbrush, what software do i need? – hopefully it is free, or at least under 1000k.

As I have found little on this topic in the forums any help would be appreciated,

shane

Attachments