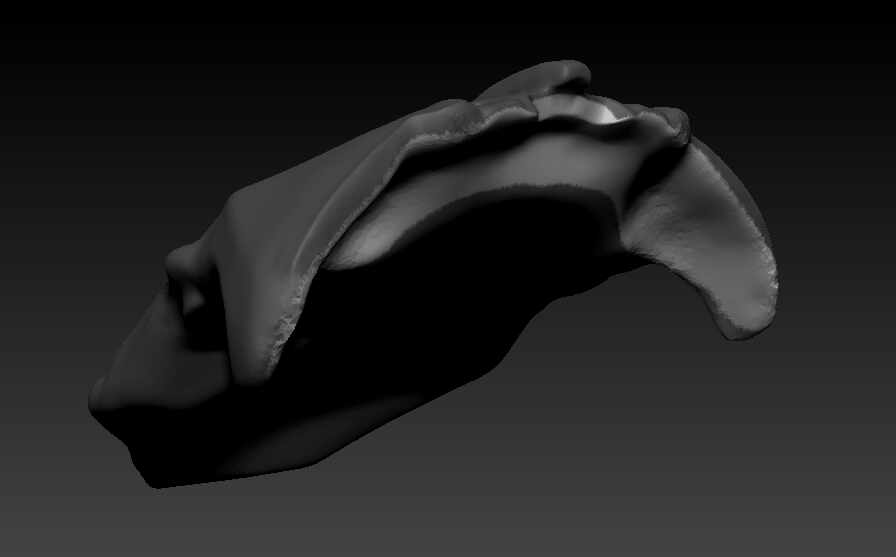

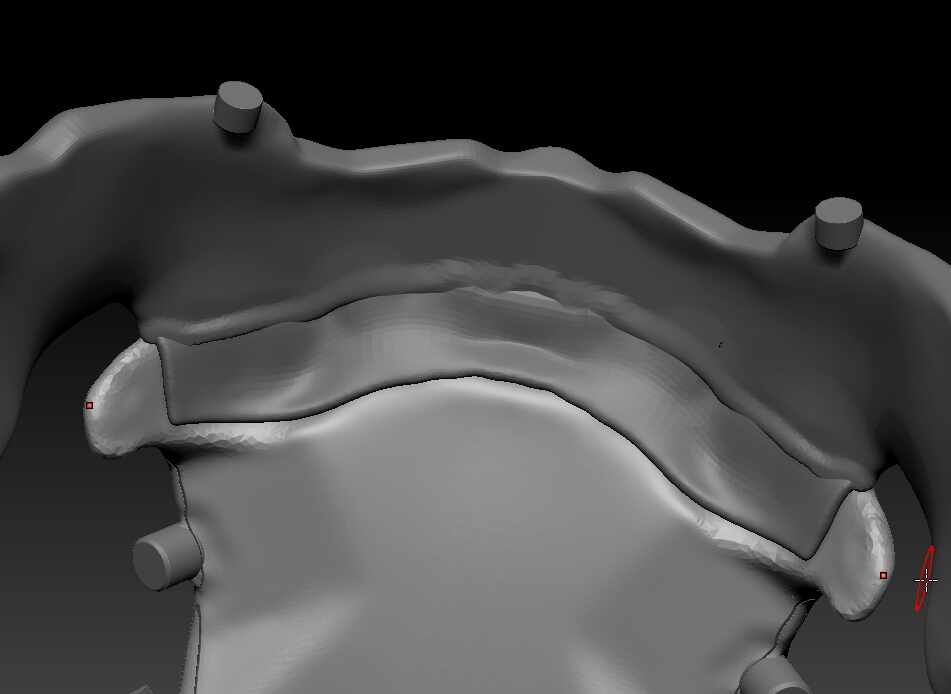

I’m making a helmet, it consists of several shields. I will print them in parts, so I need their parts to match perfectly for better gluing. at the same time, there should be a small gap between them (due to the specifics of 3D printing), so a simple boolean will not work.

how can I do it better? adjusting the walls manually is a long job, and the gap will still be uneven.