yes, you can sand and polish the sculpture, you can use knife, glue, … paint … whatever you need to finish the sculpt

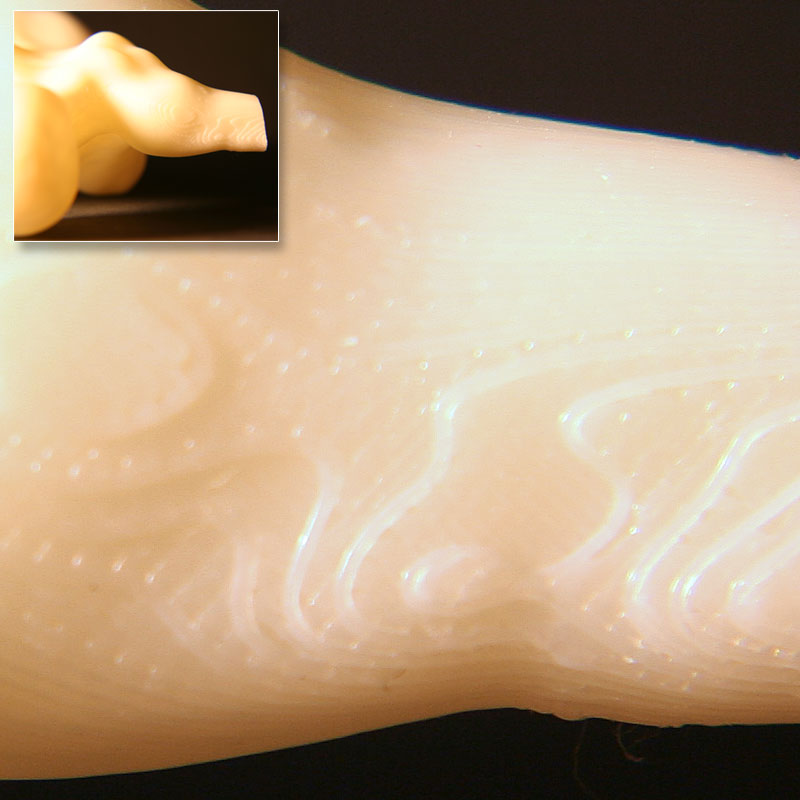

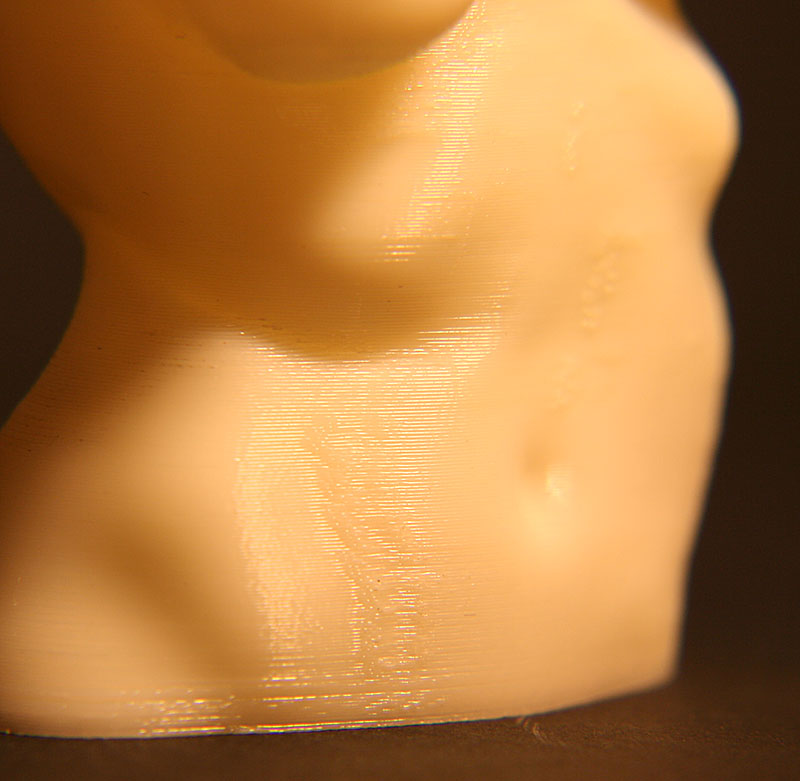

I was just pointing out the layer lines and marks on a surface as their come out of the printer, because one of ZBrush benefits is the fine detail on a model witch on a smaller size 3d prints is not reproduced

I agree - everyone should have a 3d printer !

I remember when we were kids and we draw with ‘0’ and ‘1’ on ZX Spectrum - and then one day came the guy with portable B&W printer for Spectrum - wow, he was the coolest. This days everyone has a color printer …

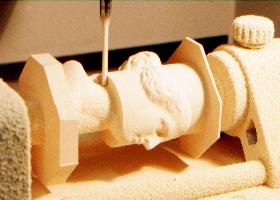

… so I am already planning where to put it … I would definitely give up drinking cool beer for this machine …

[attach=71113]3dprintdream.jpg[/attach]

Attachments