Ok, Ziggy.

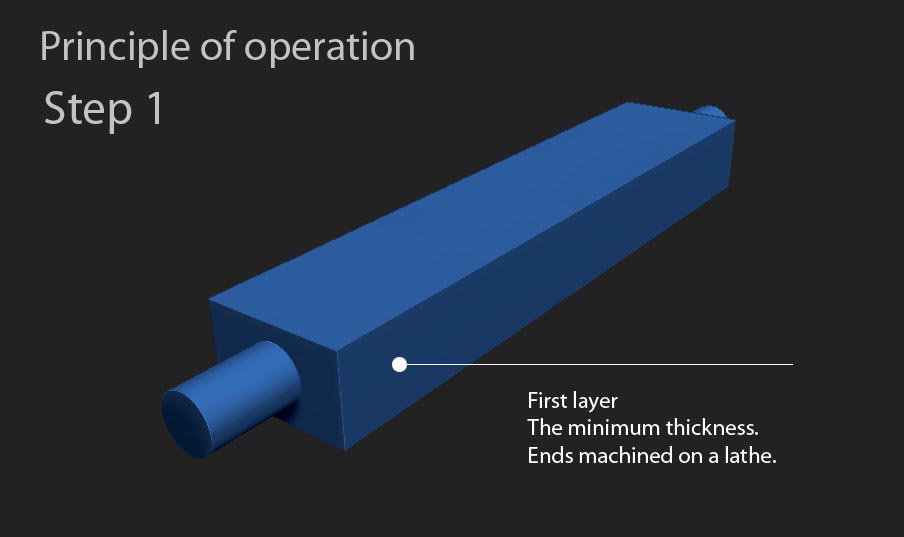

I’ll share my modest experience in wood carving CNC

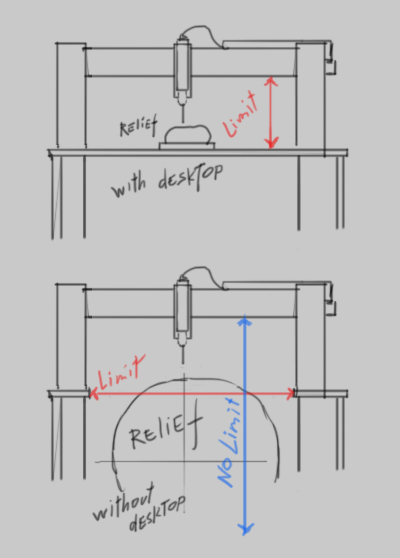

I’ll start with the disadvantages CNC. They have the limitation of motion of the spindle axis Z to the surface on the desktop.

This prevents a large volume dial details.

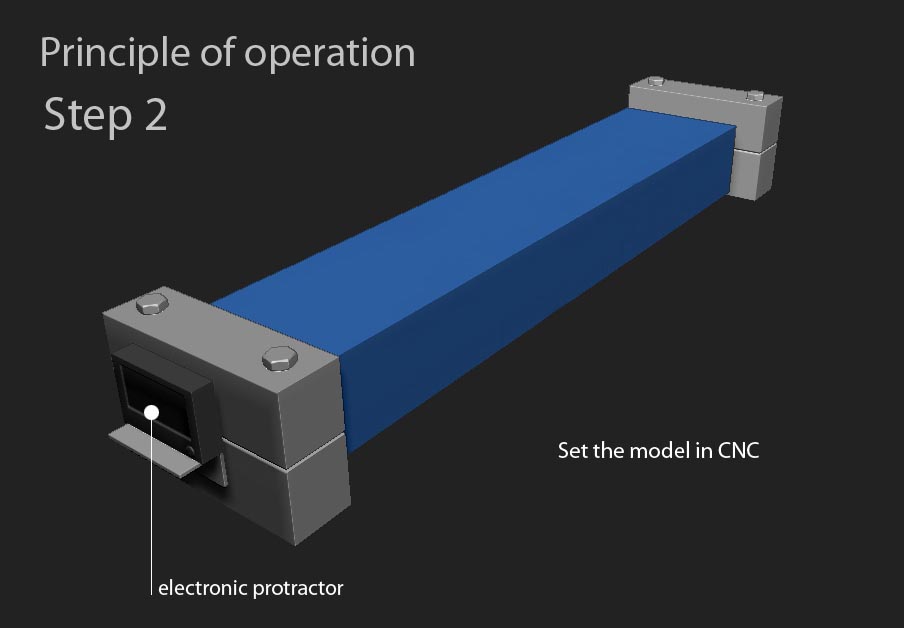

Our solution was so - remove the desktop. It was the right decision and allowed the model to increase the thickness of the width of our machine.

Look at this.

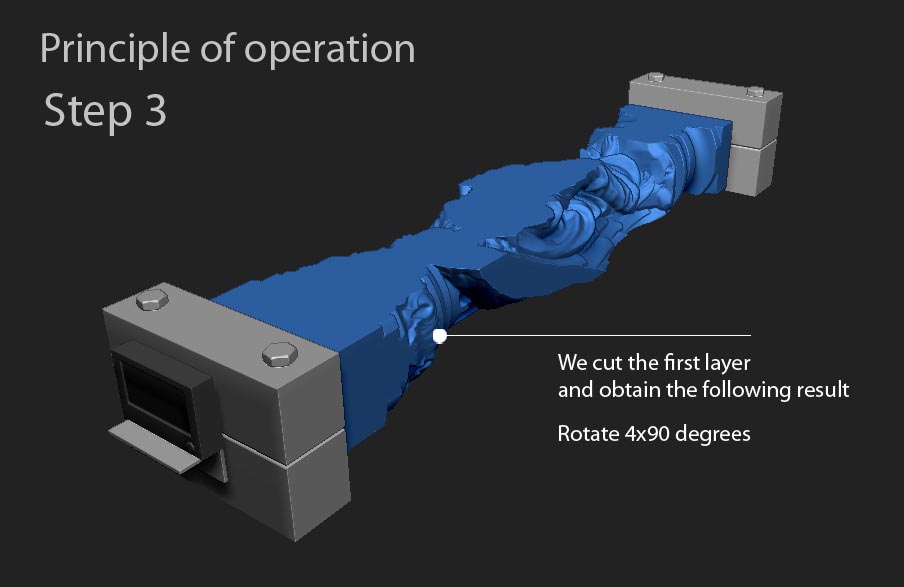

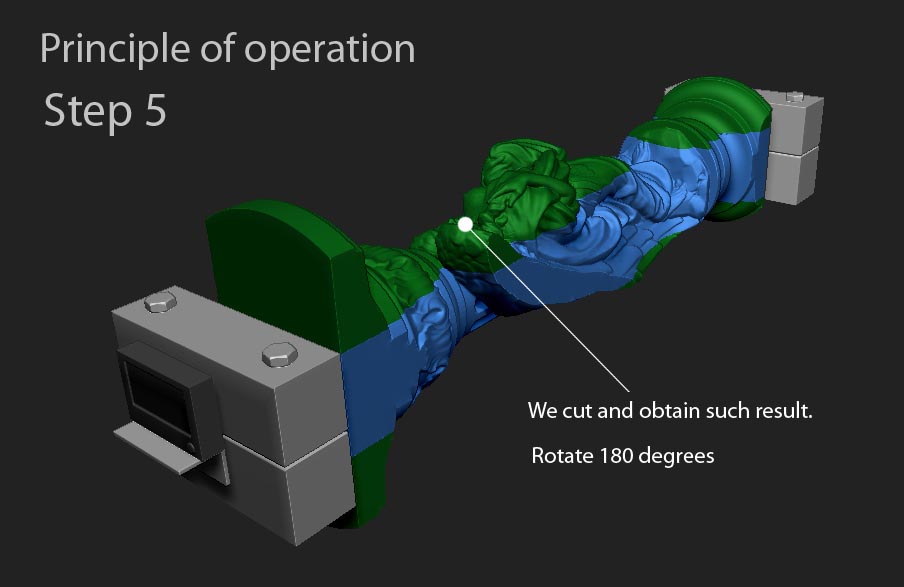

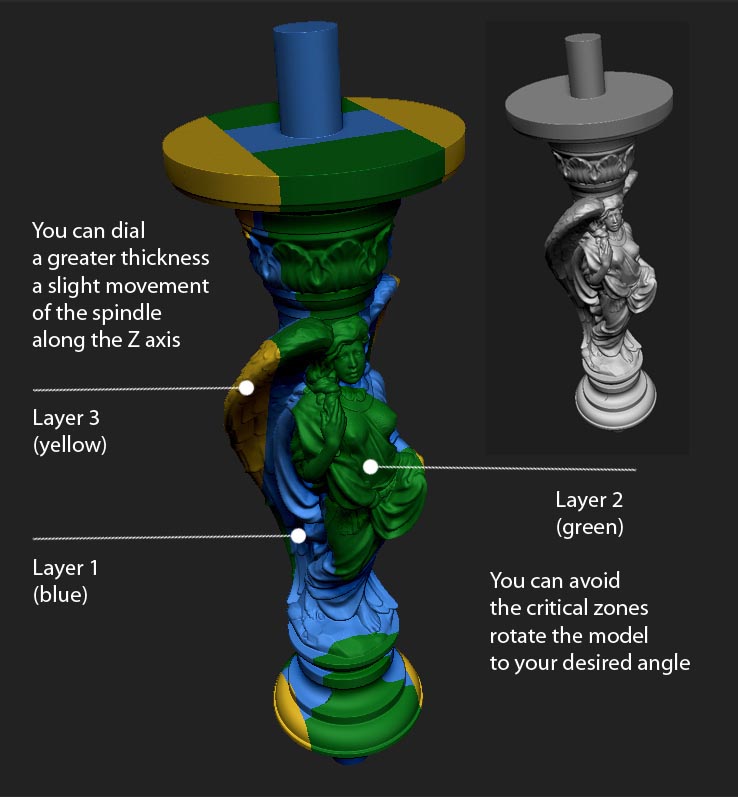

Now you can rotate the model.

raise and lower. For this device can make any turner.

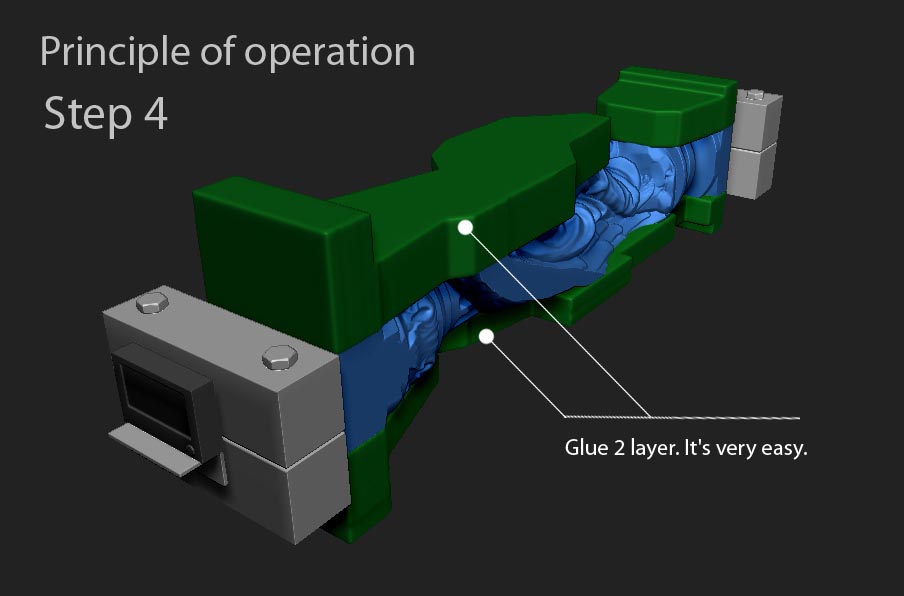

Now I think the basic idea is clear.

Everything is simple.