Thanks for the encouragement blackfangwolf

Now to catch you guys up on the latest with development on my Fungisaurs IP, since the earlier post on DesignerCon 2016.

My wife, Hwa, and I decided that since the demand for the painted toys was so large, we’d have to find a way to launch mass-production of the toys by Dcon 2017.

Our solution was Kickstarter, but it quickly became clear we wanted not only to create toys, but an entire kid’s brand including a mobile game and animation.

I first started with Trademarking and Copyrighting everything Fungisaurs for animation/game/toys with the US Patent Office.

I’ve never launched a toy line before but I figured it involves 3 things, marketing, production and distribution.

We put off distribution to worry about after we had product, so our task was two-fold marketing and production, which go hand in hand, but I’ll start with Production first.

Production:

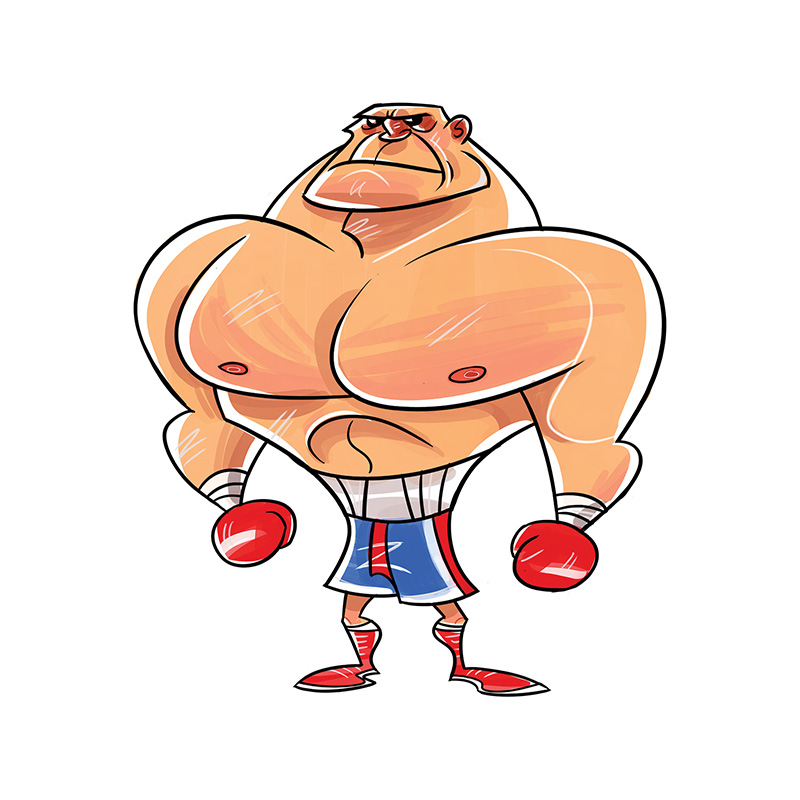

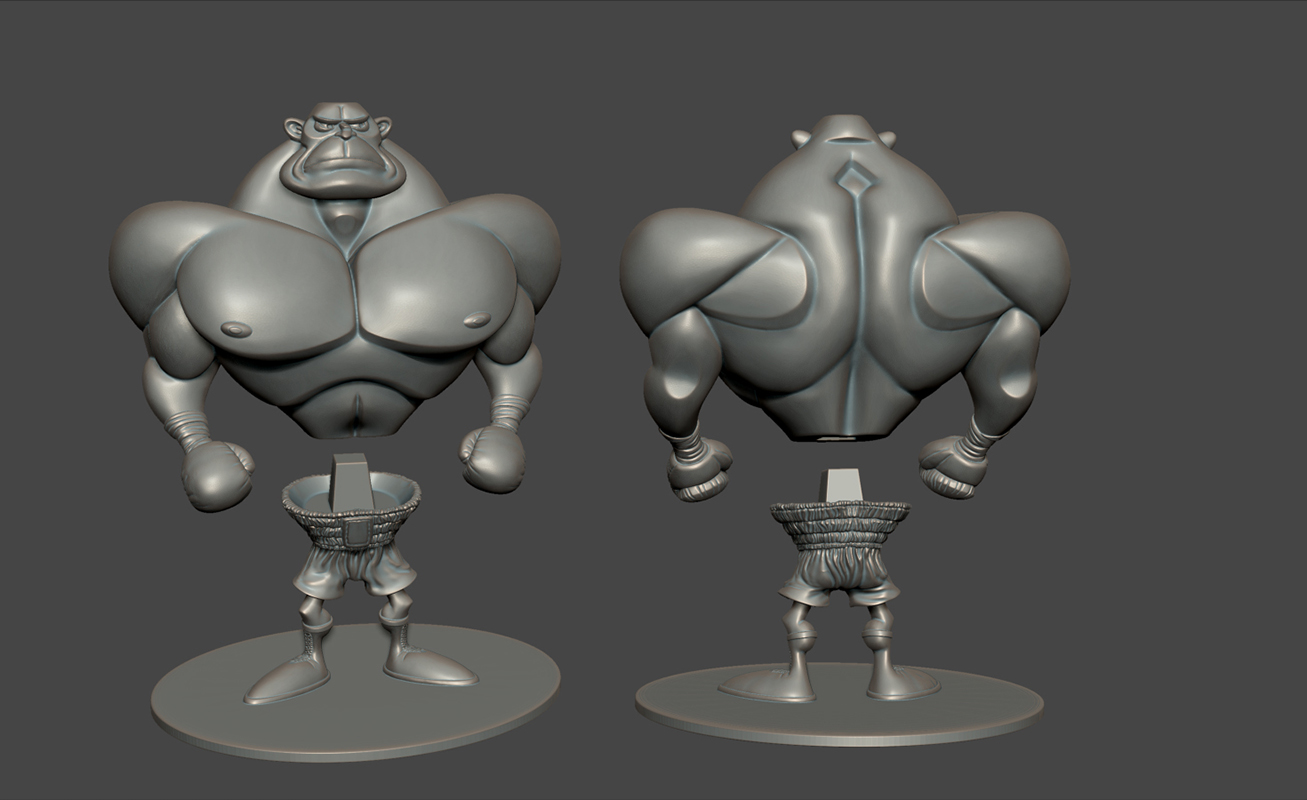

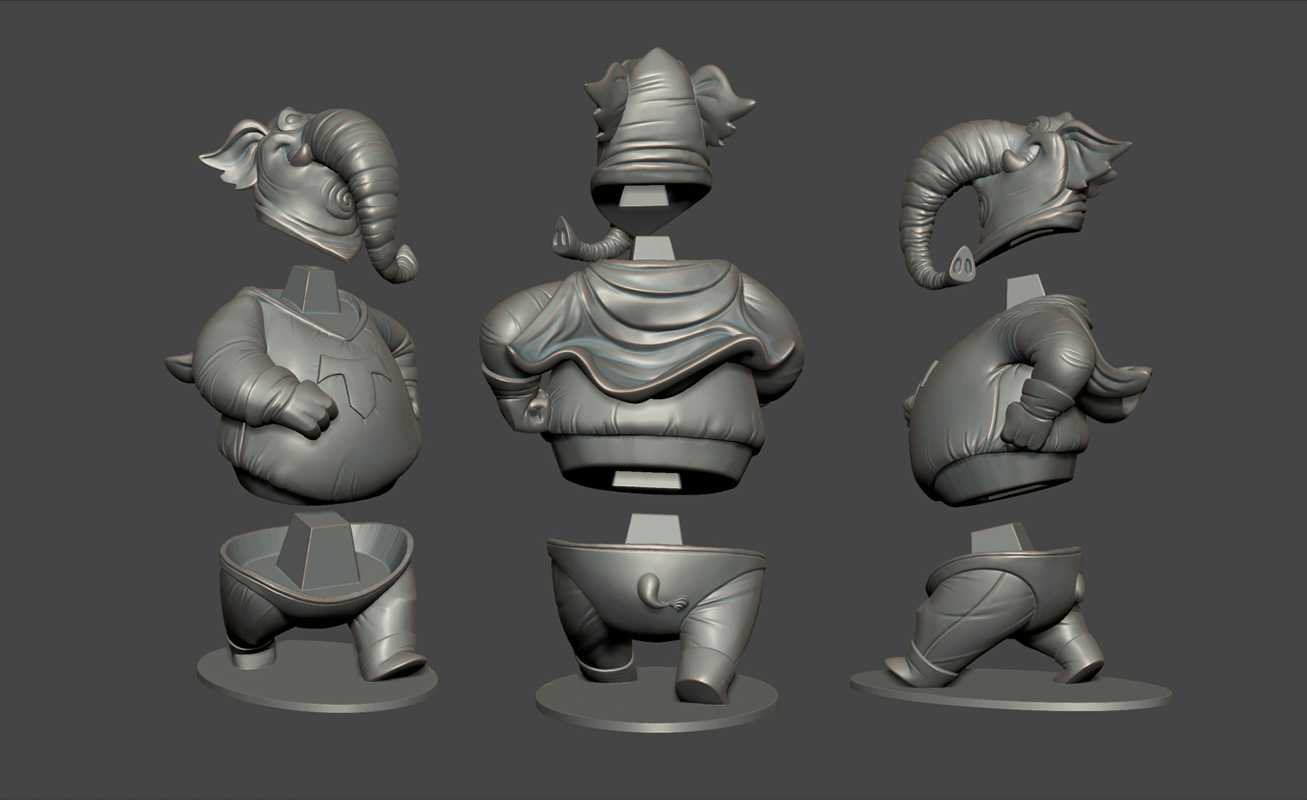

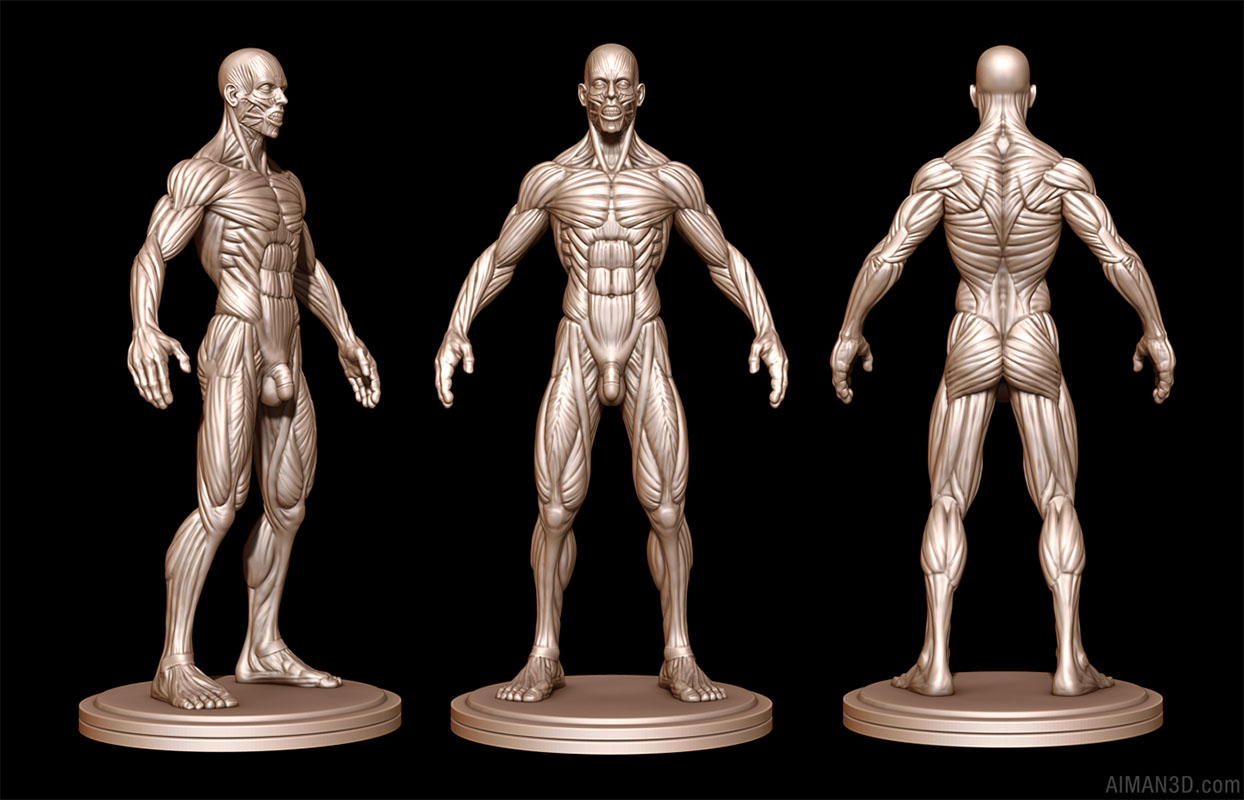

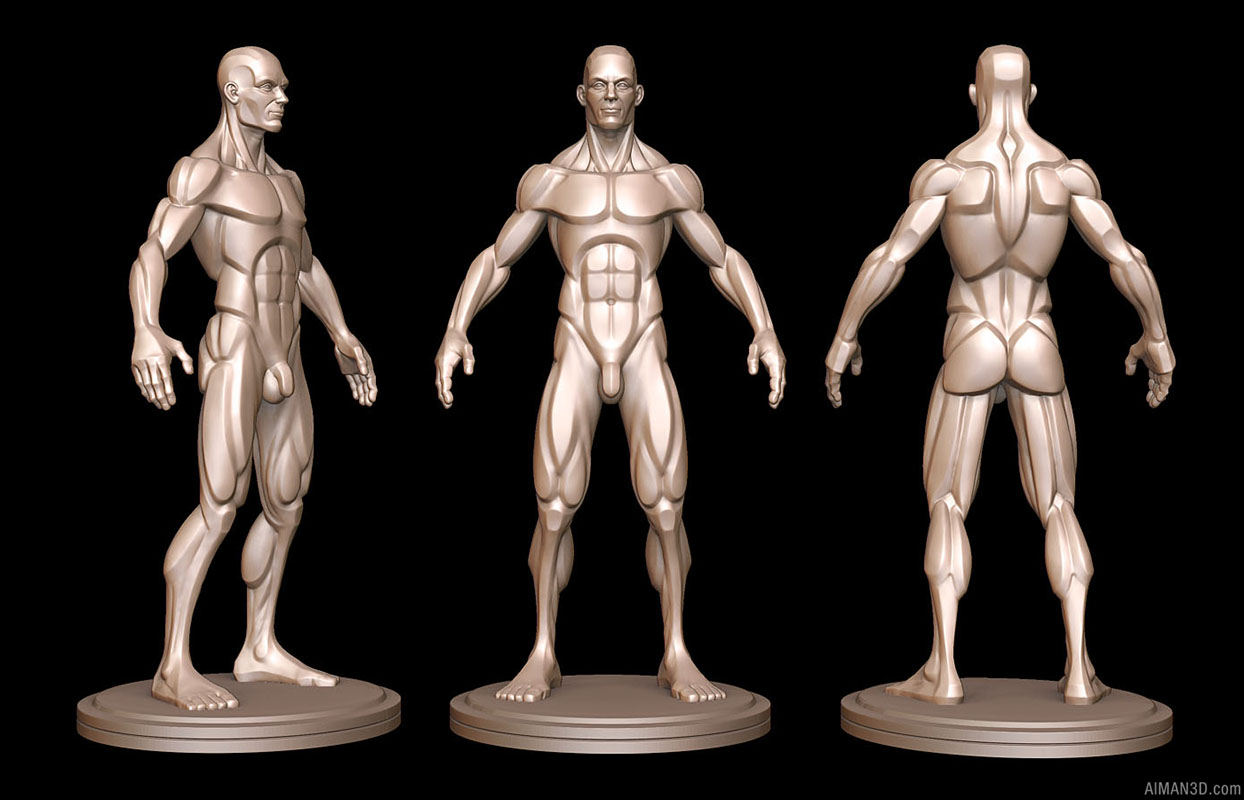

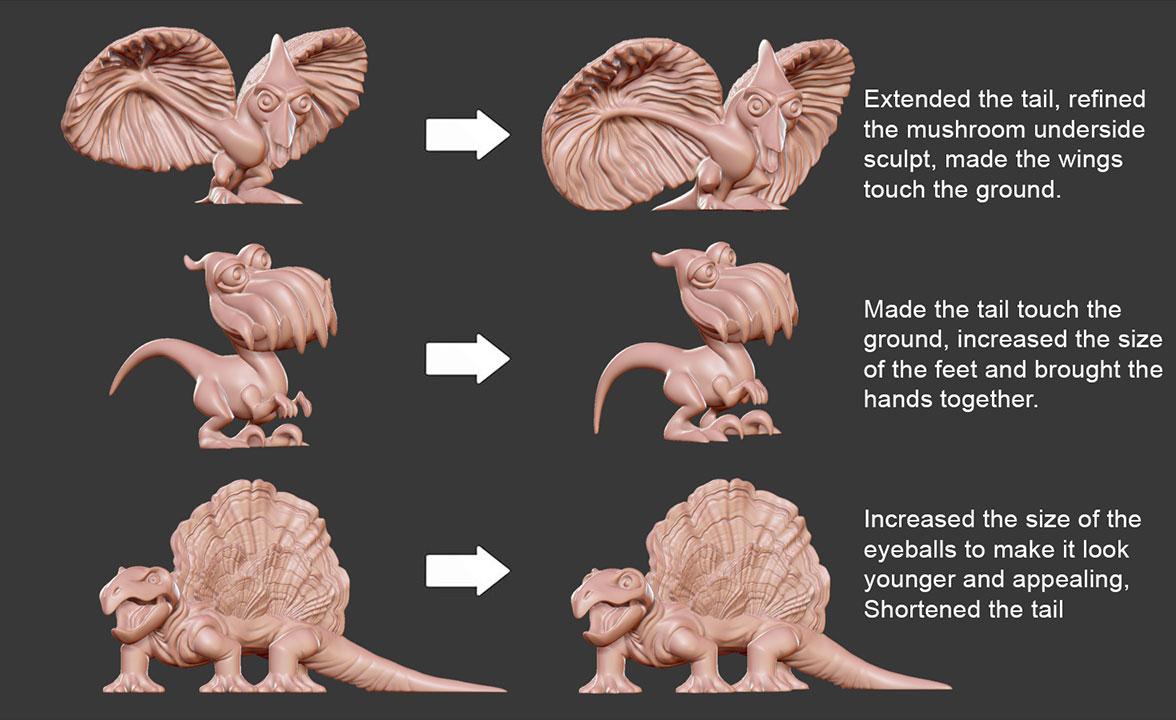

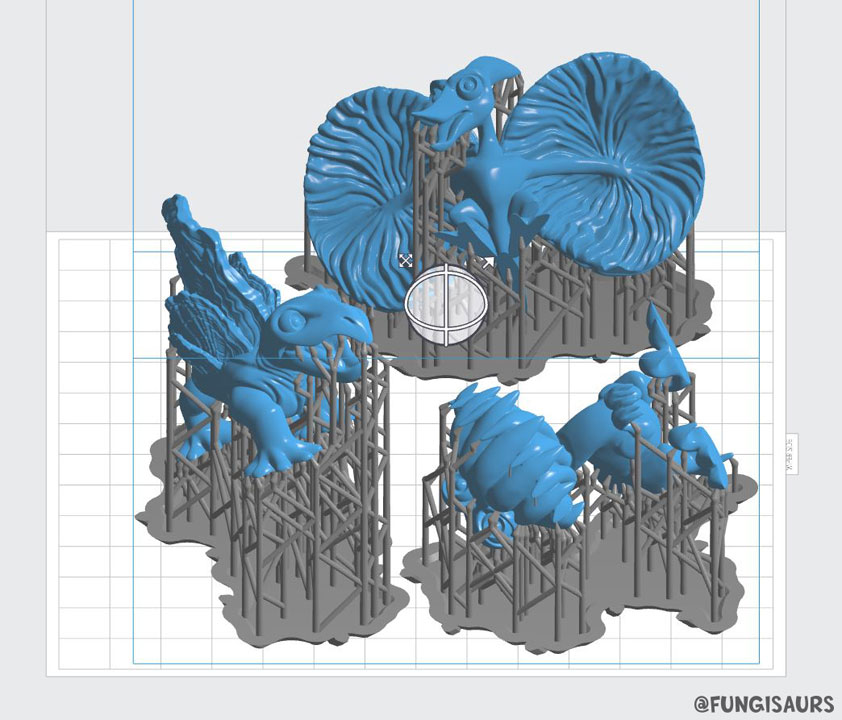

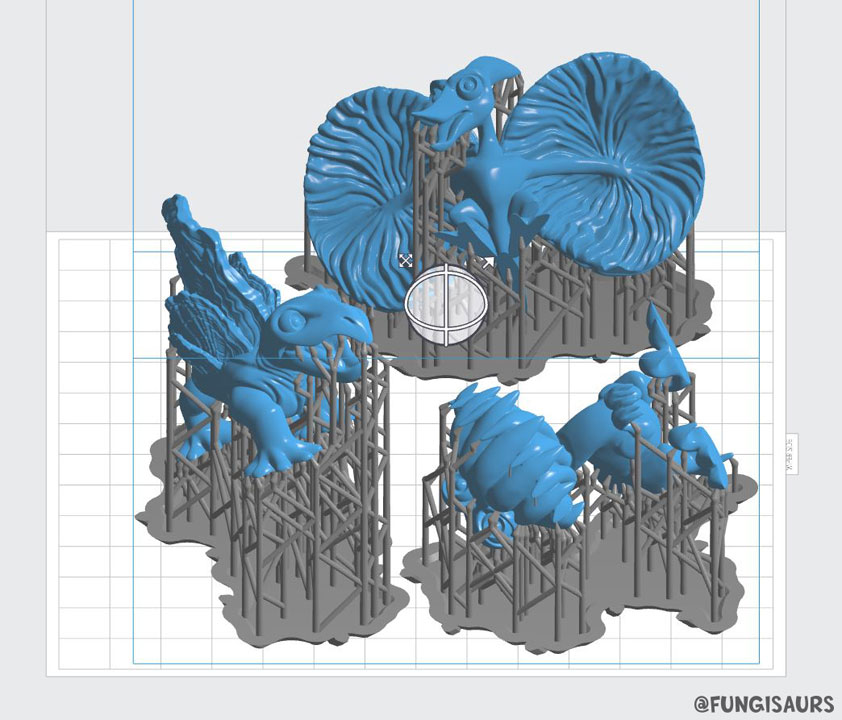

Step one of production was in my control. Because I had a 3D printer, I could create and test my own toy prototypes.

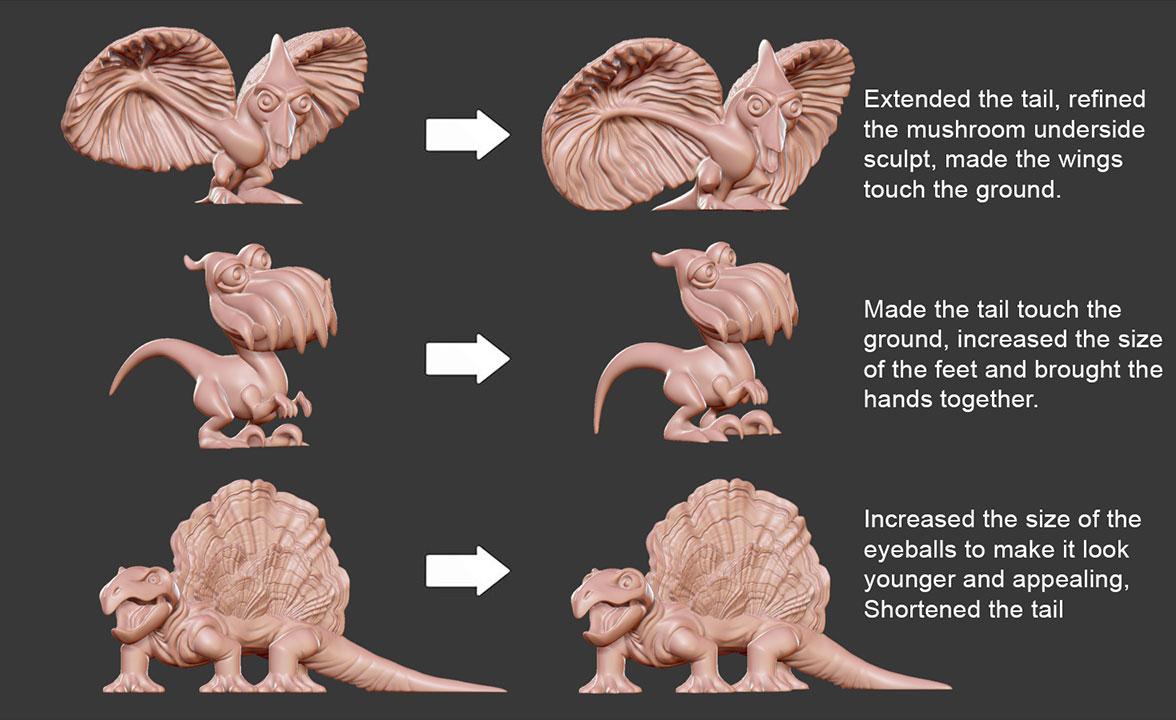

I had to create several prototypes of each character to make sure the toys were the same relative-scale, didn’t have sharp pokey-edges, were well balanced, free-standing, and wouldn’t break easily if dropped.

This involved sculpting in ZBrush, exporting out to Preform using the 3D Print Hub plugin, testing the prints, and rinse and repeat.

Beyond prototypes, I spent most of 2017 trying to get in touch with toy factories and getting them to quote me for a 12 pack set of mystery box toys. This was done by old fashioned research on sites like Ali Baba and reaching out to factories directly. This didn’t work.

Most factories didn’t respond and if they did, couldn’t speak English or their prices for injection molding were outrageous or they could not accommodate smaller orders and my plan of 16,000 units was considered a small order. There was another dimension to consider which was IP theft and I couldn’t trust factories that someone hadn’t already worked with and recommended.

I started reaching out to anyone and everyone I knew in the toy industry and friends of friends. This worked better.

Eventually I found a factory recommended through a friend and after several rounds of emails we came to an agreement on the cost of 16,000 toys (8 toys in series one of Fungisaurs X 2000 units each) + packaging + 12-pack display packaging for around $25K USD. (I’d rather not recommend the factory or mention them here until I’ve gone through the entire process from start to finish and be confident in saying they did a good job, so don’t ask before summer 2018)

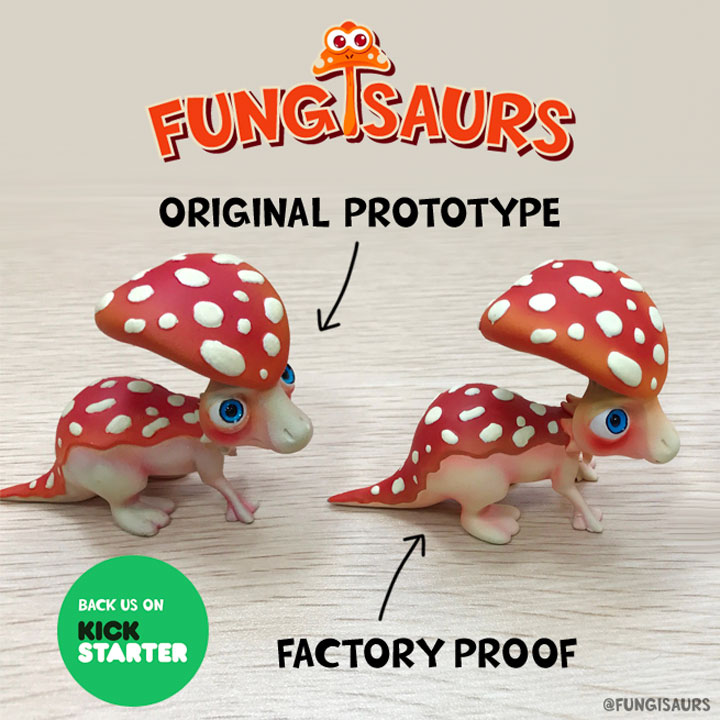

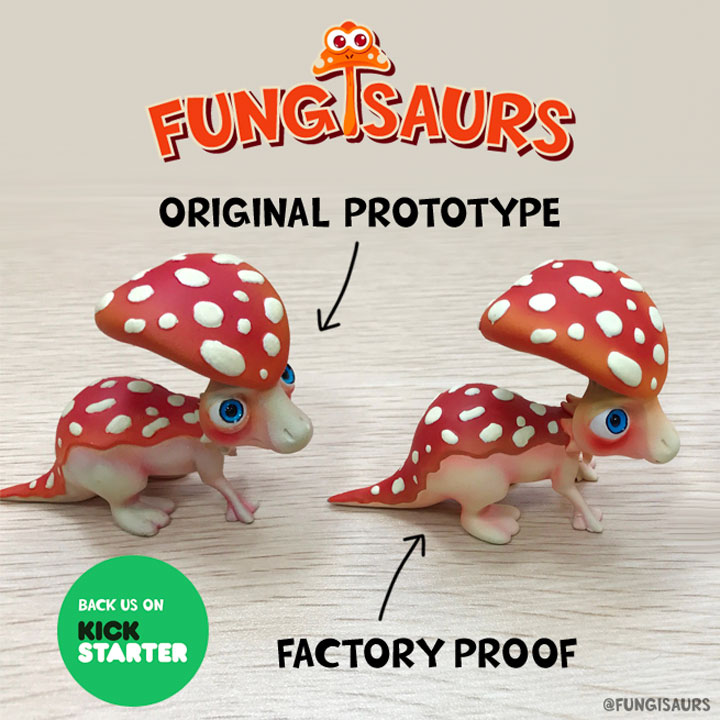

After pricing and timeline were negotiated, the next thing was to ensure the quality of their work was up to my standards. Toy production is an expensive up-front endeavor. In order for me to see their quality for just one toy I’d need to pay them to make the metal injection molding tool, which was far too expensive. I was mostly concerned with finished surface quality and paint, so I decided to ship them a 3D print, have it painted by their factory painters and see how close they could match my friend Elvin Rodriguez’ paintjob.

I was very happy with the results and with the toy company’s communication and availability, so I gave them the thumbs up and moved to the task of raising the funds to make the order.

Another big part of production was the branding. This was all handled by Hwa. Her design chops and experience wen’t a long way to creating a cohesive Fungisaurs look that evokes outdoor adventure and appreciation for nature.

I created some renders and traced those renders in Illustrator to create shapes for enamel pins, Hwa setup the new website, Kickstarter graphics, app UI, and all the merch.

Despite it being only her second go at toy package design, Hwa was able to nail the feel I was going for the Fungisaurs mystery-box individual and 12-pack display box.

After we had a series of products, we had to answer some basic questions to create a compelling backstory for people to care about our designs.

1. What’s a Fungisaur?

This was a chance to explain the concept but also declare a mission statement for the brand. This is what we came up with:

Fungisaurs is the name we’ve given our original dinosaur-mushroom hybrid species. We hope to inspire adventure, science education and appreciation for nature through toys, games and animation.

2. How many kinds of Fungisaurs exist?

We left this open ended so I could continue to make more Fungisaurs designs, just saying that 8 species had been “discovered” so far.

3. Where did Fungisaurs come from?

This was a toughie as it required the most storytelling and it became my main priority. I wrote up a big origin story script and several character descriptions of humans that inhabit the world of Fungisaurs.

I first contacted an illustrator/concept artist on Artstation, Ryan Winch, to come up with character designs based on my descriptions, in his own, animated style which I thought was a good fit for the brand.

After a few rounds of revisions I was absolutely stoked with his designs.

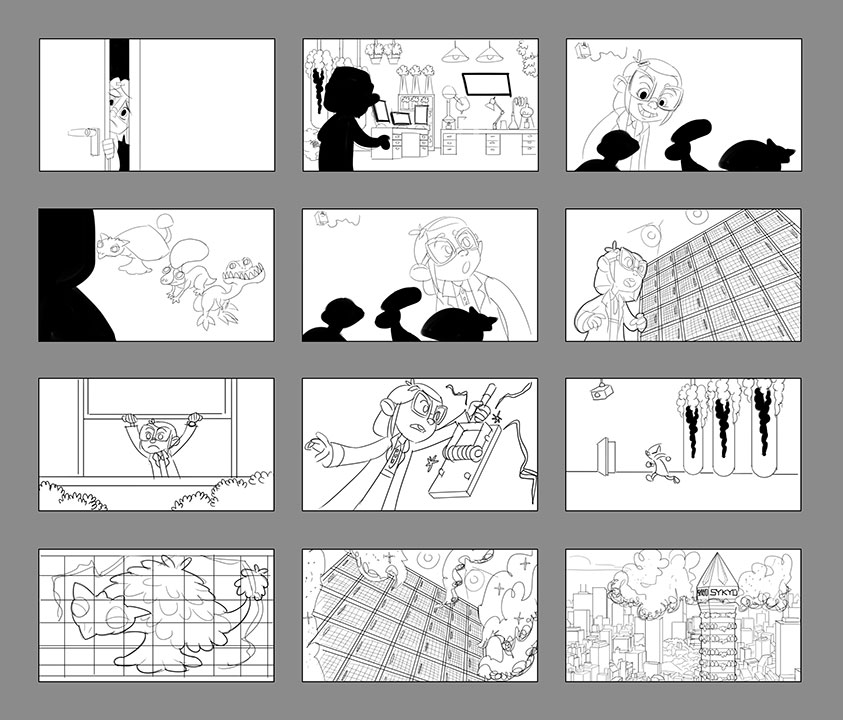

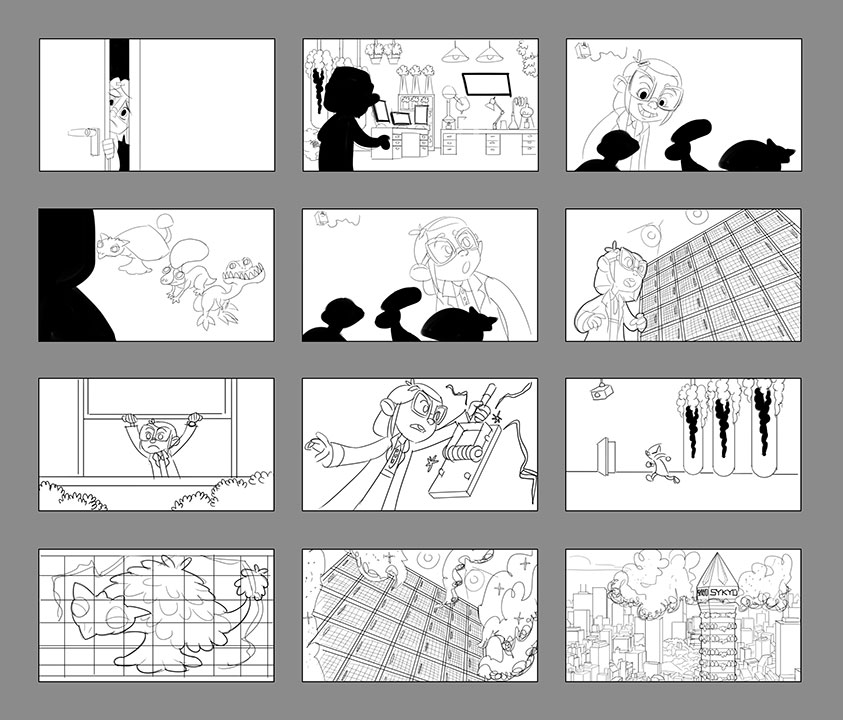

I then contacted a college friend and storyboard artist, Feras Khagani, to help board the first draft of my animated backstory.

I reached out to my friend Cat Arthur to help with the audio, composing a score and sound effects.

The primary voice acting was all done by another friend Megan Ring, who was the perfect voice for Kei, my young protagonist.

The remainder, illustrating and animating the story was all on me, and I’m not gonna lie, this was a challenge.

I had the experience being a generalist for several years in Chicago, and I preferred to do 3D animation, but there was no way I could animate a nearly 3 minute story in 3D, by myself.

I decided to go the Aftereffects route and animate the origin story in 2.5D.

I hoped the animation would be done by Dcon 2017 in time for the Kickstarter launch, but there was so much work to do that it took till the middle of the campaign till I was finished.

Here’s the finished animated origin story for Fungisaurs:

[youtubehd]0qJgtPy0few[/youtubehd]

As if an animation wasn’t intensive enough, because I’m insane, I also decided to build an augmented reality mobile game demo.

I only setup the one character, C-Rex, for the demo. I started by rebuilding the high-res model at a relaxed pose, then made a low poly version, UV mapped it and setup all the textures, then rigged it and animated 3 different cycles in Maya.

I contacted Zack Rock, an excellent game programmer friend I had worked with at a previous gig, to help me build the app.

We literally built an app in 3 days using Unity, Apple AR Kit and Xcode. Here’s a video of the working demo.

[youtubehd]mVfsw4Af2Vc[/youtubehd]

So for the fruits of our labor we got to launch a Kickstarter for our own toy line on the day of DesignerCon 2017 like we had planned.

As of this post we’re almost at the end of our 30 day campaign. You can check it out and support (if it’s still active) here: http://kck.st/2jbL70U

It was absolutely a team effort and also good to keep in mind, all of this production/development was done over the course of 2017, in our free time, when we were not freelancing and working around LA in a professional capacity. (which was most of the time)

In the next post I’ll talk more about our strategies in marketing the Kickstarter.