such a great work man.just love it. small_orange_diamond:D

small_orange_diamond:D

hello guys,

first of all i want to thank you for the great summit 2014.

it was a blast ! i´ve been watching every minute of it via the stream

here from germany.

all the artists were so inspiring. and the new features of zbrush 4r7

will be amazing. can´t wait to get my hands on it.

i really love you guys !

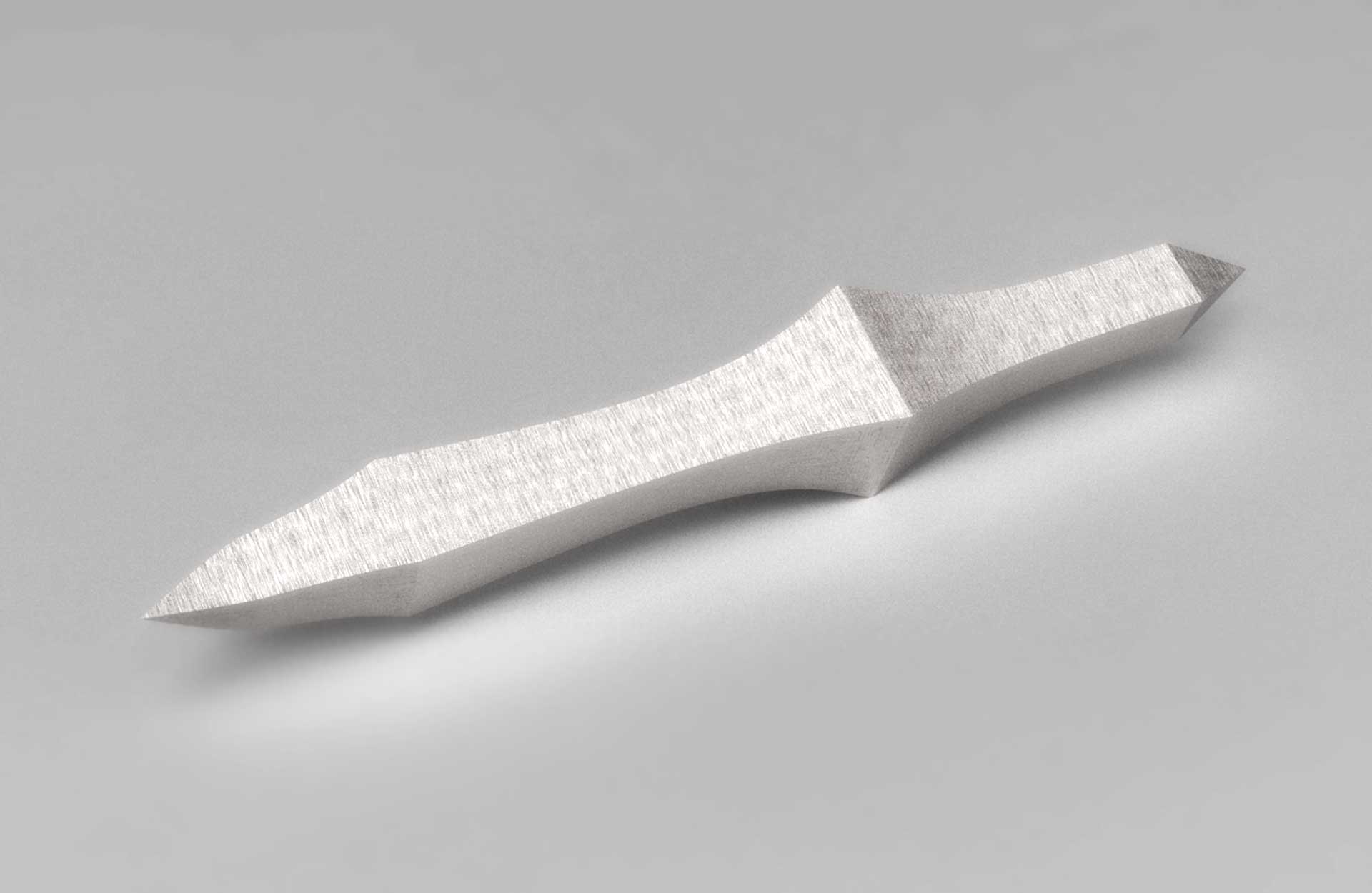

here is a new project i´ve been working on.

it´s 89,47 grams of silver ! - guys - this is a beast !

it was printed on a solidscape plotter and then cast in silver.

hope you like it - i definitely do

cu soon

cosmic

forgot this one: hang loose

i hope i don’t kill myself with that

Das ist ganz gutt mein Herr… in plain English Great Work… you should whole the item, still getting bulk but less weight and expense…

Hello Sigmund,

thank you very much. it was a lot of fun to create that one.

i first thought about hollowing out the model. but the weight

is absolutely ok. i worn the ring the whole day. and its not too

heavy. you forget it after five minutes of wearing.

it just has to be that massive and heavy

it is arched inside and the feel is perfect. doesn´t annoy at all.

just another information to the people:

please don´t get me wrong:

the cracks, bumps etc. in the ring aren´t there because of a

poor 3d printer.

the 3zpro is able to print the finest details and far beyond that.

the cracks, blood splatter etc. are there because i put them there

inside of zbrush.

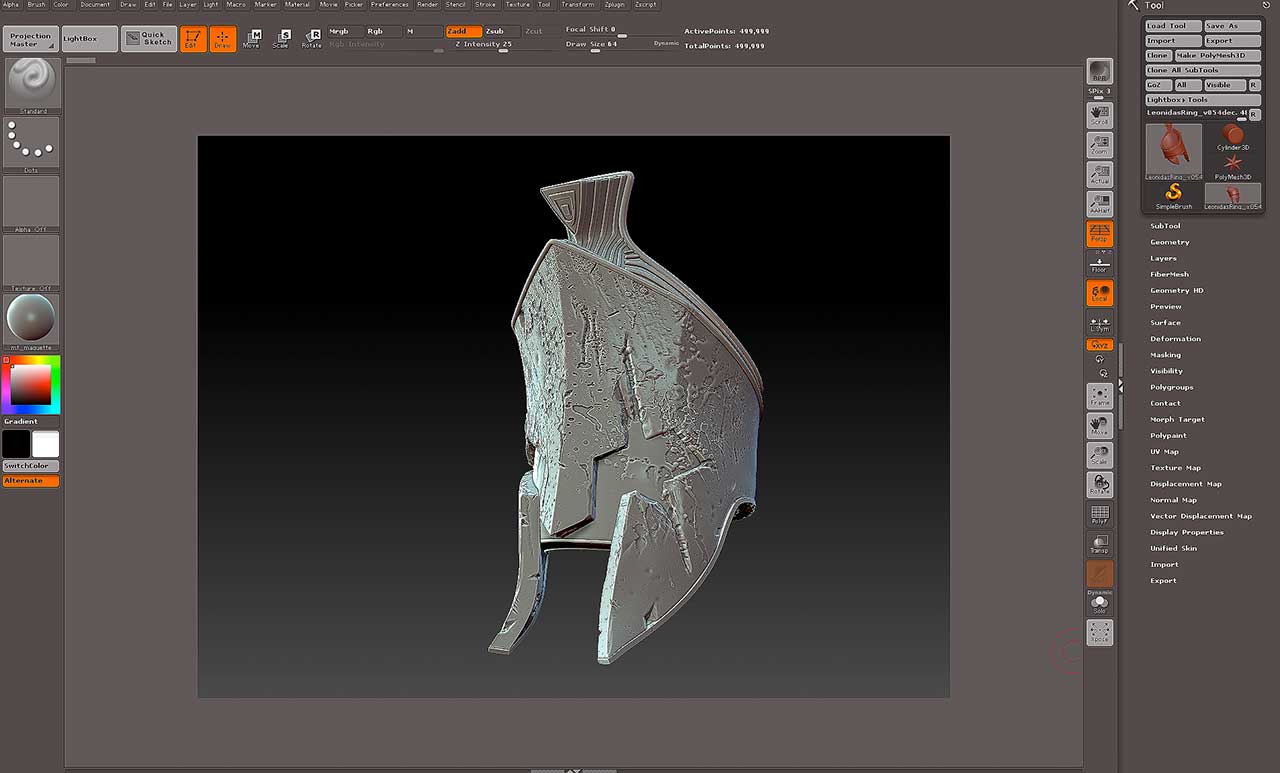

here´s a screenshot of the 3d model inside of the best software in

the world

I want one!

Hi dmonk,

thank you very much - but i´m sorry, this one in particular

is a unique piece and unfortunately not meant for sale.

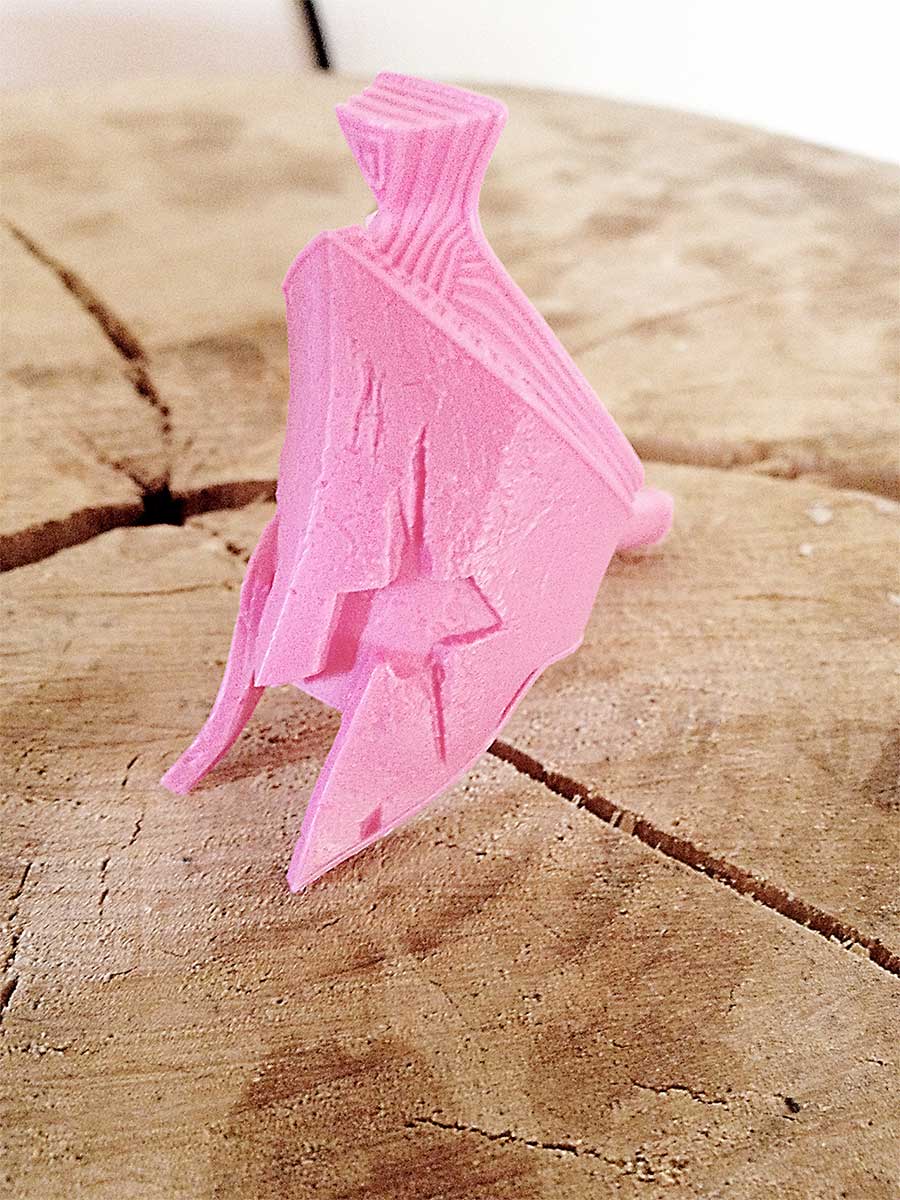

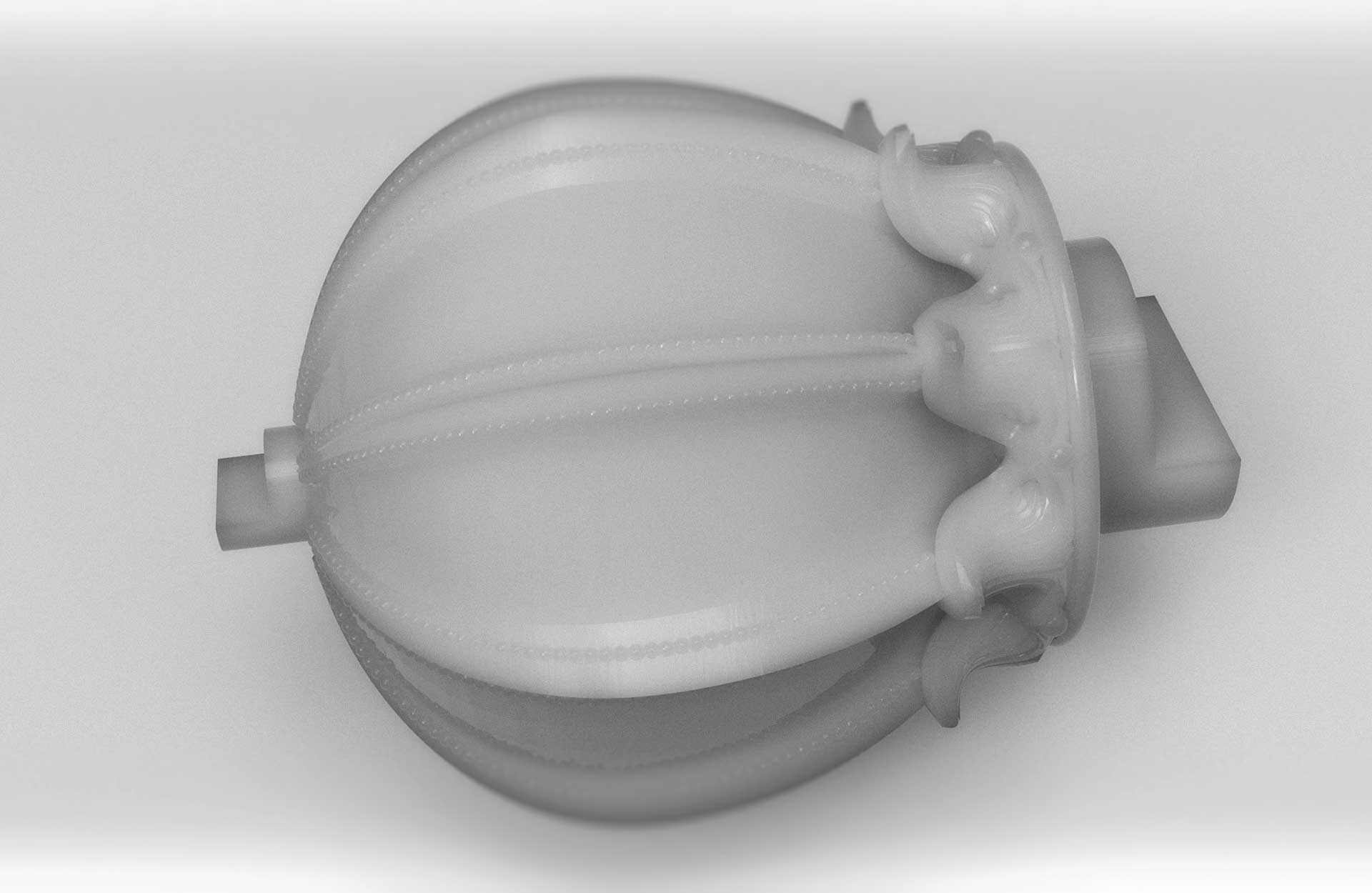

here is a photo of the wax object before it gets placed inside

a vessel, then filled with cement, then burned inside the oven and

after that comes casting in silver. then comes sawing, grid blasting, polishing,

blacking, more polishing …

an insane amount of effort in every tiny workstep with lots of source of

error - but it is worth every second

Where do you get your wax prints done? Looks great!

Hello,

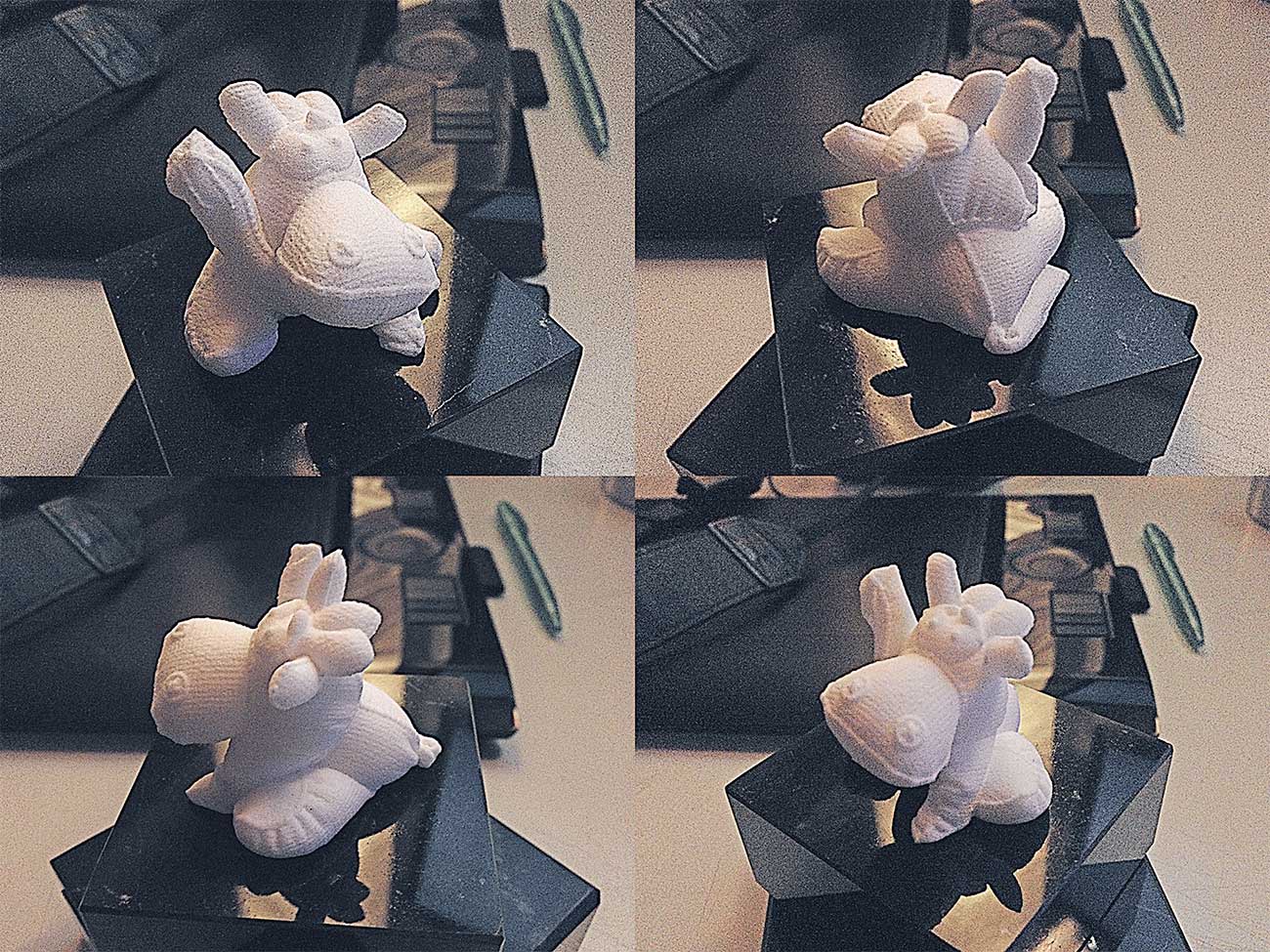

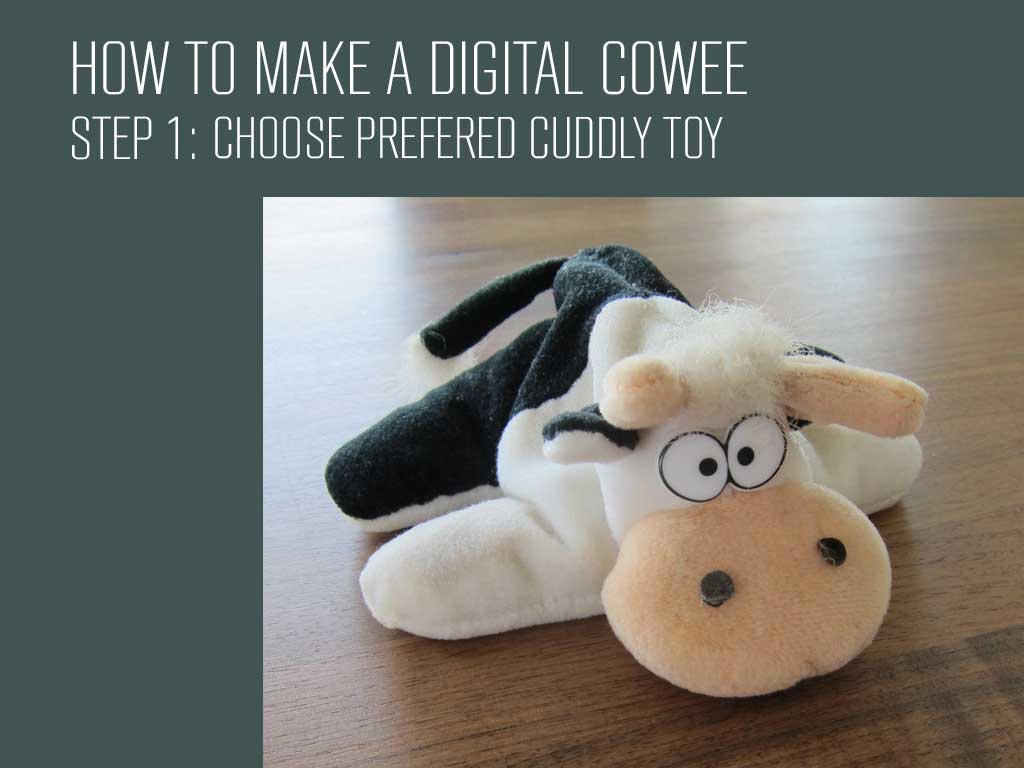

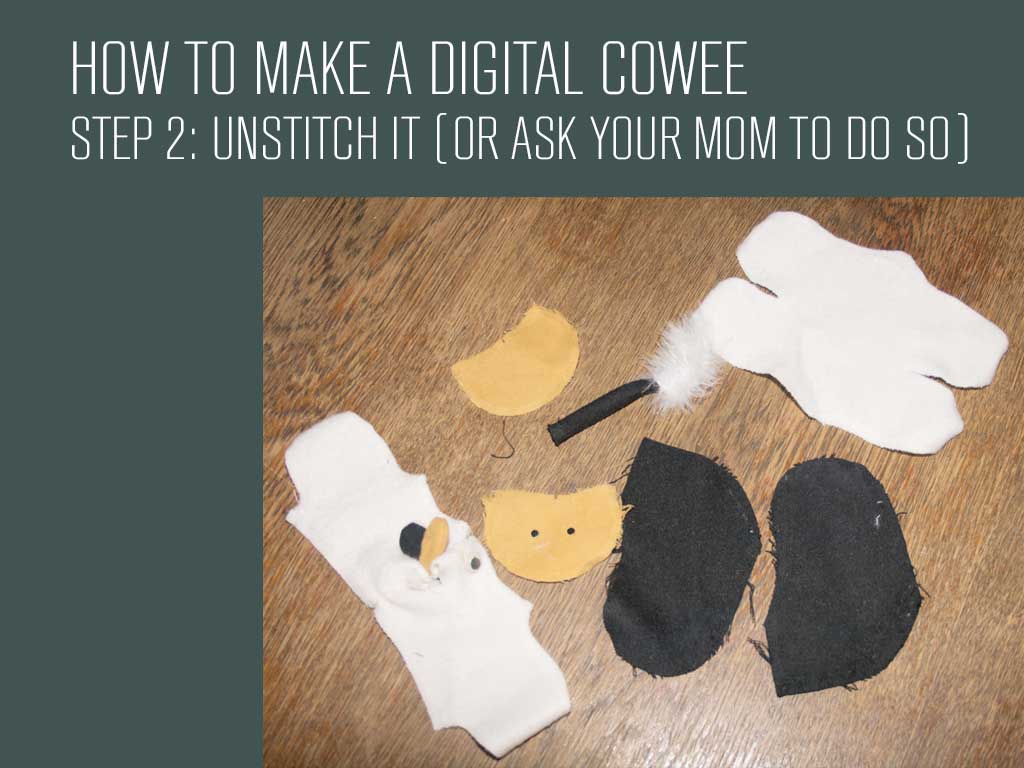

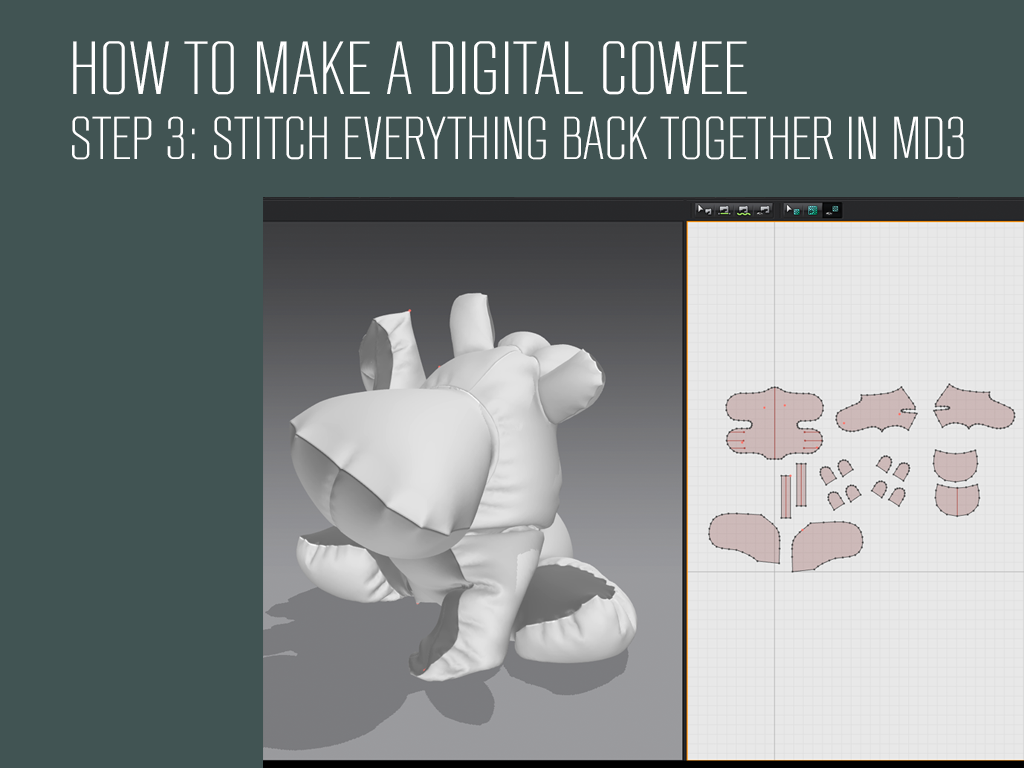

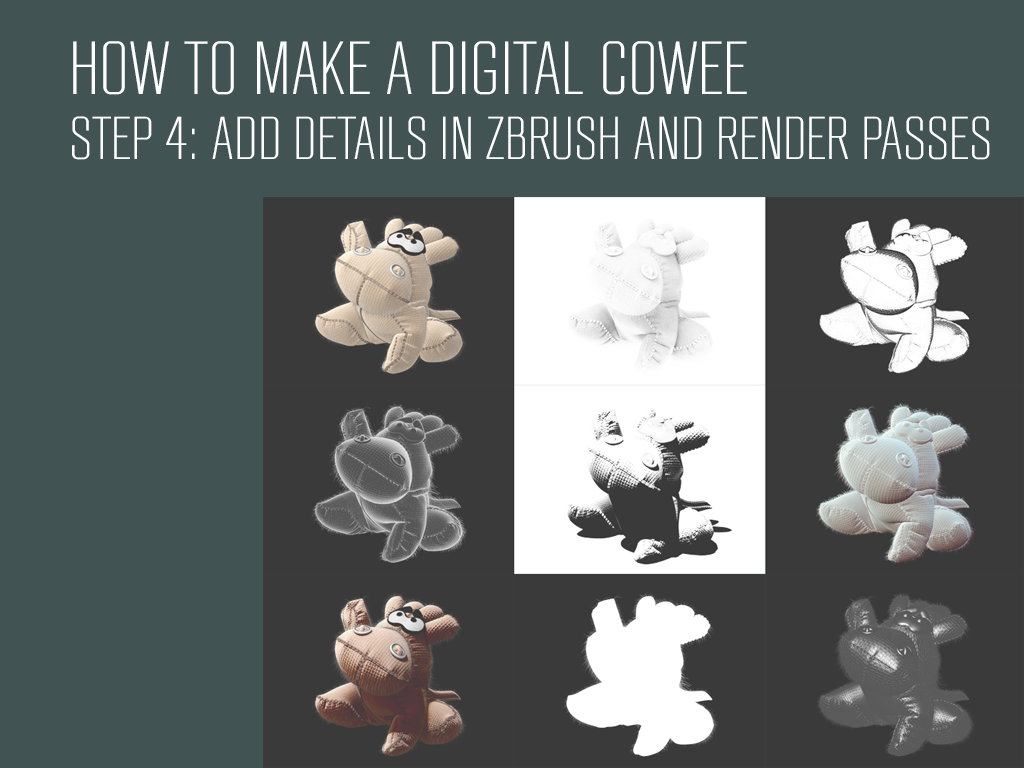

this is another work i did.

the workflow is pretty cool i think:

unstitch your favourite cuddly toy of choice, sew it back together in marvelous designer

and then add details, seams etc. in zbrush. using insert brushes with the help of polygroups

is a very handy feature.

and then do a 3d print of it.

Clever idea and lovely cowee sculpt

glad my stuffed animals don’t see this thread  , clever idea indeed…

, clever idea indeed…

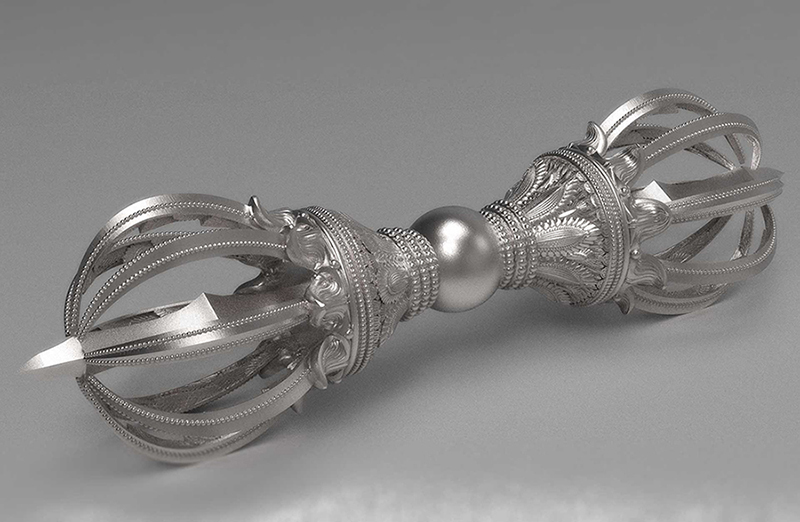

Dear Zbrush friends,

today i want to show you a work i´ve been working on for the last 5 months.

its a so called vajra which i created in zbrush for a customer of mine.

I have the kindly permission to share this with you.

A vajra is a buddistic symbol which means thunderbolt and diamond.

It is a ritual tools spread from india along with indian religion and culture.

Every pearl, every leaf and every „tooth“ is placed there not just randomly

but follows a special meaning and a special iconography.

It was 3d printed in wax and then cast in silver.

all parts are welded together with highend lasers.

Everything was 3d printed on solidscape machines.

It wasn´t possible to make it from one piece because you have to be able to

demold it from the silicone model.

so i had to split it in different pieces.

guys, this is serious business. and it was so hard work to do.

Creating the Vajra model inside of zbrush is one part,

but creating all the forms for the casting is a different story.

It was pleasure and pain at the same time. and i learned so much from it.

We are all talking about 3d printing etc. these days but this is really pushing

the envelope of what is possible with today´s 3d printing technology to the limit.

we used water-soluble waxes for the inner forms of the crown.

just to be able to demold the parts.

imagine: the water-soluble wax has a fading factor of 30%.

you have to keep all that in mind to get a perfect result.

it was so much trial and error till we reached a satisfiying result. and every minute

was worth it in the end

its a mixture of art and all the technical aspects you face when you do something like this.

this is not just playing around with zbrush - doing something like this is not only fun.

you don´t want to know how much coffee i need

modeling something like this in zbrush is one part of the story - but to get it into the

real world as a perfect silver model - guys this was really hard work. with all aspects of

mould making, casting, finishing and costruction.

the boolean operations for the negative forms i made with netfabb pro.

this all wouldn´t be able with such a perfect software like zbrush. but i really hope for

a 64 bit version to be able to do more details, more precision, more precise boolean operations etc.

If you like what you see and get a little bit of a glimpse what this is all about - please give me a little bit of a

feedback. i would feel honored.

please dont just skip this.

As an artist who tries every day since years to create good work - with long times of no sleep - this would

really mean the world to me. - from guys who really understand what this is all about.

best regards,

yours

cosmic ollie

Great, yet another brilliant piece… what are the dimensions of this one?

When I go back to your first piece, the heart and wings one… was this polished, as I seem to lose a lot of detail and this one has brilliantly fine detail…

Keep it up and the posts/your work is very inspiring…

Ziggy

Hello Ziggy,

thank you very much for you comment.

You´re right polishing these pieces is extremely tricky.

if you overdo it all details are washed away.

The foundry has special polishing machine that works with

a rotating magnet field and inside of a basin with water there

are fine needles that polish everything.

but 1 minute too long and all is smooth and the work is for nothing.

i´m not doing this by myself there are very experienced people doing this.

it´s an art for itself.

more works coming soon

have a nice day, best regards and i soo hope for a soon release of the

new version of zbrush  -> 64 bit (oh my, we will all have so much fun and more

-> 64 bit (oh my, we will all have so much fun and more

possibilities with it)

yours cosmic ollie

Cosmic Ollie…

I see you mention the Solidscape, ask your friends helping you if the ProJet 3500 CPXMax is not better… I maybe needing one on my side of the world soon… or if they have any better machines they can recommend?

Looking forward to your next piece here…

Regards Ziggy

Hi Sigmund,

nice to hear from you.

i´ve been busy.

franky speaking I´m just a zbrush guy and i dont have any experience

about all the machines, casting techniques and finishing.

But the next time i get to talk to the printing / casting guys i´ll ask them.

News coming soon -

cu cosmic

(waiting every day for the 4r7 release

Dear community,

i´m soo happy and i want to share this with you:

This week was the baselworld exhibition in switzerland and i participated in the

solidscape 3d printing competition.

my model „violin“ took first place in the „fine art“ category.

my buddy patrick from everydayswiss went there and took a bunch of photos

which i want to share with you.

-> „hey man - next year i want to see an entry from you too !!

the 3d plot was done on a solidscape machine and was provided by hobach in

idar oberstein. guys, thank you so much for your support.

cu soon.

yours cosmic

Congrats! I like your “violin” model and print

let the battle begin